Lithium Iron Phosphate (LiFePO4) batteries have gained significant attention in recent years due to their impressive safety profile, long cycle life, and environmental friendliness compared to other lithium-ion battery chemistries. They are widely used in applications such as electric vehicles (EVs), renewable energy storage, and portable electronics. However, despite their many advantages, LiFePO4 batteries are not without their challenges. The biggest problem with LiFePO4 batteries lies in their lower energy density compared to other lithium-ion chemistries, which limits their applicability in certain high-energy-demand scenarios. This article will explore this issue in depth, as well as other associated challenges, and discuss potential solutions and future directions for improving LiFePO4 technology.

The Energy Density Challenge

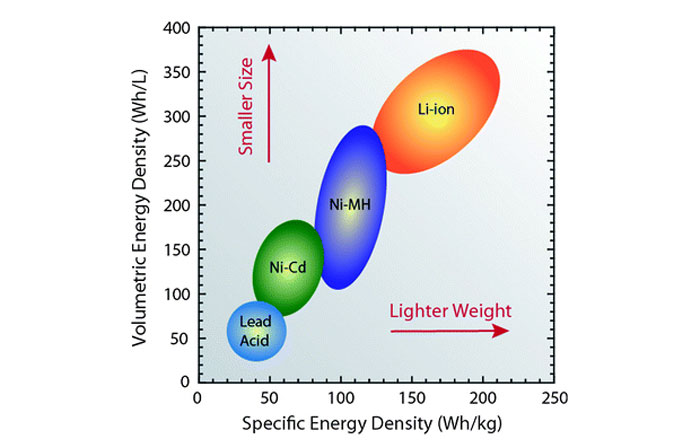

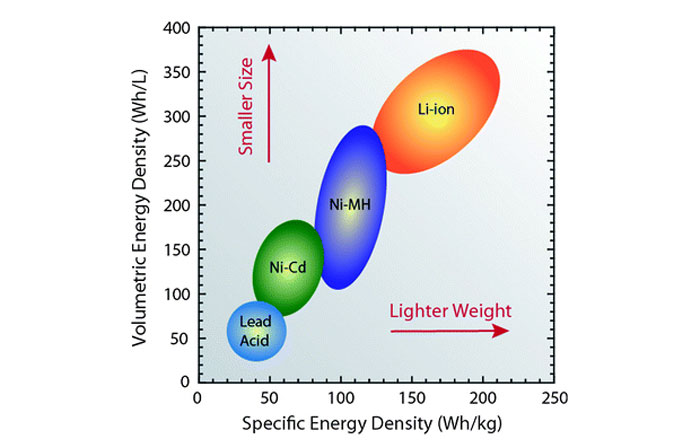

Energy density refers to the amount of energy a battery can store relative to its size or weight. It is typically measured in watt-hours per kilogram (Wh/kg) or watt-hours per liter (Wh/L). LiFePO4 batteries have an energy density of around 90-160 Wh/kg, which is significantly lower than that of other lithium-ion chemistries such as Lithium Cobalt Oxide (LiCoO2) or Lithium Nickel Manganese Cobalt Oxide (NMC), which can achieve energy densities of 150-250 Wh/kg or higher.

Why Is Energy Density Important?

-

Portability and Space Constraints: In applications like smartphones, laptops, and electric vehicles, higher energy density allows for longer usage times without increasing the size or weight of the battery.

-

Range Anxiety in EVs: For electric vehicles, energy density directly impacts the driving range. A lower energy density means either a shorter range or a larger, heavier battery pack, which can affect vehicle performance and efficiency.

-

Renewable Energy Storage: In grid storage systems, higher energy density allows for more compact and efficient energy storage solutions, reducing the footprint and cost of installation.

Why Is LiFePO4's Energy Density Lower?

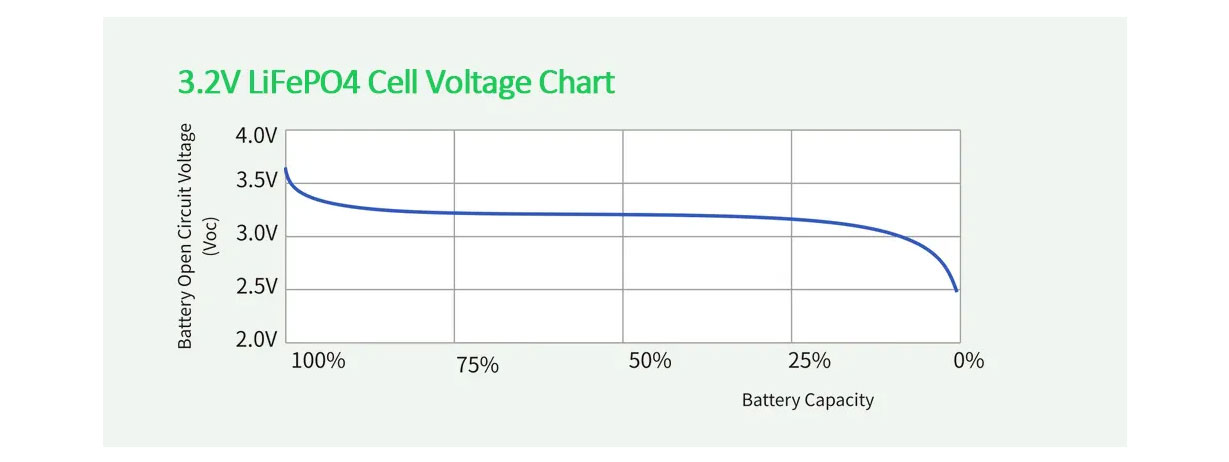

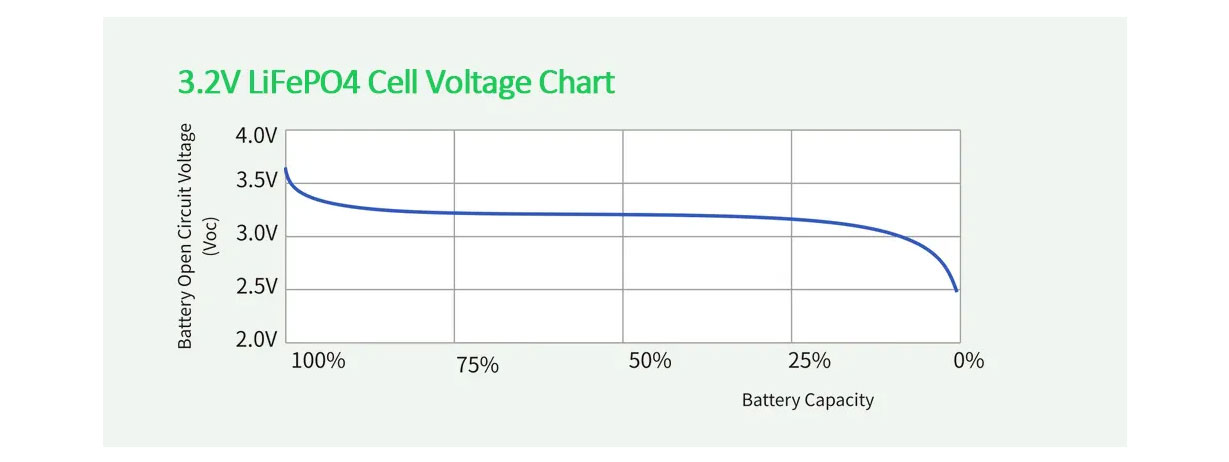

The lower energy density of LiFePO4 batteries is primarily due to the chemistry of the cathode material. LiFePO4 has a lower voltage (3.2V nominal) compared to other lithium-ion chemistries (e.g., 3.7V for LiCoO2), which directly reduces the energy output per cell. Additionally, the phosphate-based cathode material is inherently less dense than cobalt or nickel-based cathodes, further limiting the energy storage capacity.

Other Challenges Associated with LiFePO4 Batteries

While energy density is the most significant drawback, LiFePO4 batteries also face other challenges that can impact their performance and adoption:

Lower Voltage Output

The nominal voltage of LiFePO4 cells is 3.2V, which is lower than the 3.7V of other lithium-ion chemistries. This means that more cells are required to achieve the same voltage in a battery pack, increasing the complexity, size, and weight of the system.

Temperature Sensitivity

Although LiFePO4 batteries are known for their thermal stability and safety, their performance can still be affected by extreme temperatures. At low temperatures, the internal resistance of the battery increases, reducing its efficiency and capacity. At high temperatures, while the risk of thermal runaway is lower compared to other lithium-ion batteries, prolonged exposure can still degrade the battery over time.

Cost and Material Availability

While LiFePO4 batteries are generally cheaper than cobalt-based lithium-ion batteries, the cost of raw materials like lithium and iron phosphate can still be a concern, especially as demand for these materials increases. Additionally, the production process for LiFePO4 batteries is more complex than for some other chemistries, which can drive up manufacturing costs.

Charging Speed

LiFePO4 batteries typically have a lower charging rate compared to other lithium-ion chemistries. While they can still be charged relatively quickly, they may not be suitable for applications that require ultra-fast charging, such as high-performance electric vehicles.

Possible Solutions and Improvements

To address the challenges associated with LiFePO4 batteries, several solutions are being implemented to enhance their performance, affordability, and practicality.

Cost Reduction Through Mass Production

As demand for LiFePO4 batteries continues to grow, economies of scale are driving down production costs. Advances in manufacturing processes, automation, and material sourcing are making these batteries more affordable. Additionally, increased competition among battery manufacturers is further pushing prices down.

.jpg)

Improved Battery Management Systems (BMS)

Newer and more advanced BMS technologies are improving the safety and efficiency of LiFePO4 batteries. Smart BMS solutions with real-time monitoring, automatic balancing, and thermal protection help prevent overcharging, deep discharging, and temperature-related issues, extending battery life and ensuring optimal performance.

Thermal Management Solutions

To counter the temperature sensitivity of LiFePO4 batteries, various heating and cooling solutions are being integrated into battery packs:

-

Self-heating technology: Some batteries now include built-in heating elements to enable safe charging in cold environments.

-

Passive and active cooling systems: Improved ventilation and liquid cooling methods are being used in high-power applications to maintain stable operating temperatures.

Higher Energy Density Designs

Although LiFePO4 batteries have lower energy density than other lithium chemistries, advancements in electrode design and cell structure are gradually increasing their capacity without compromising safety. Innovations such as silicon-doped anodes and new electrolyte formulations are helping to enhance energy storage capabilities.

Development of Recycling Programs

Efforts are underway to establish efficient recycling processes for LiFePO4 batteries. Battery manufacturers and governments are investing in new technologies to recover lithium, iron, and phosphate materials for reuse. Establishing proper recycling channels will reduce environmental impact and improve resource sustainability.

Expansion of High-Discharge Models

To improve the discharge performance of LiFePO4 batteries, researchers are optimizing the internal resistance and electrode materials to support higher current loads. This makes them more suitable for applications requiring rapid power output, such as electric motorcycles and industrial machinery.

Strengthening Supply Chains

Manufacturers are diversifying material sourcing and expanding production facilities outside of traditional markets to reduce supply chain risks. Increased investment in local battery production plants is helping stabilize supply and lower transportation costs.

By implementing these improvements, LiFePO4 batteries are becoming more efficient, durable, and widely accessible, making them a strong choice for energy storage and electric mobility applications.

.jpg)