Contents:

When it comes to maintaining solar panels, the choice of cleaning brush is crucial. The quality and characteristics of the bristles can significantly influence cleaning effectiveness and the safety of the solar panels. In this article, we will explore various aspects of bristle materials, hardness, design, durability, environmental impact, cleaning efficacy, and maintenance.

Bristle Materials

The material of the brush bristles is fundamental to its performance. Common bristle materials include nylon, polypropylene, and natural fibers.

-

Nylon: Nylon bristles are popular due to their durability and resistance to UV rays and harsh weather conditions. They are effective at lifting dirt without scratching the surface of solar panels. However, nylon can wear down over time, especially with extensive use.

-

Polypropylene: This material is known for its flexibility and resilience. Polypropylene bristles maintain their shape and effectiveness even after repeated use. They are less prone to absorption, making them suitable for wet cleaning applications.

-

Natural Fibers: Brushes made from natural fibers, such as horsehair, offer a soft touch that is gentle on solar panel surfaces. While environmentally friendly, they may not be as durable as synthetic options and can absorb moisture, leading to quicker degradation.

Each material has its advantages and disadvantages, making the choice dependent on the specific cleaning needs and conditions.

Bristle Hardness

The hardness of the bristles plays a significant role in cleaning performance. Soft bristles are ideal for routine maintenance, as they gently remove dust and light debris without damaging the panel surface. They are particularly effective for regular cleaning and are less likely to cause scratches.

In contrast, harder bristles can effectively tackle tougher grime, such as bird droppings or tree sap. However, using hard bristles requires caution, as excessive pressure can lead to surface damage. Striking a balance between cleaning power and surface protection is essential for maintaining the integrity of solar panels.

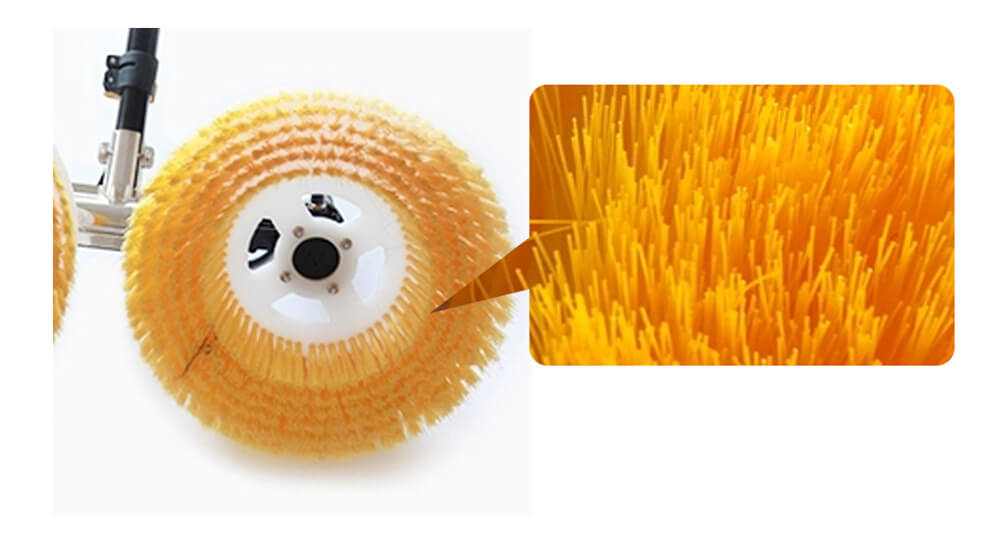

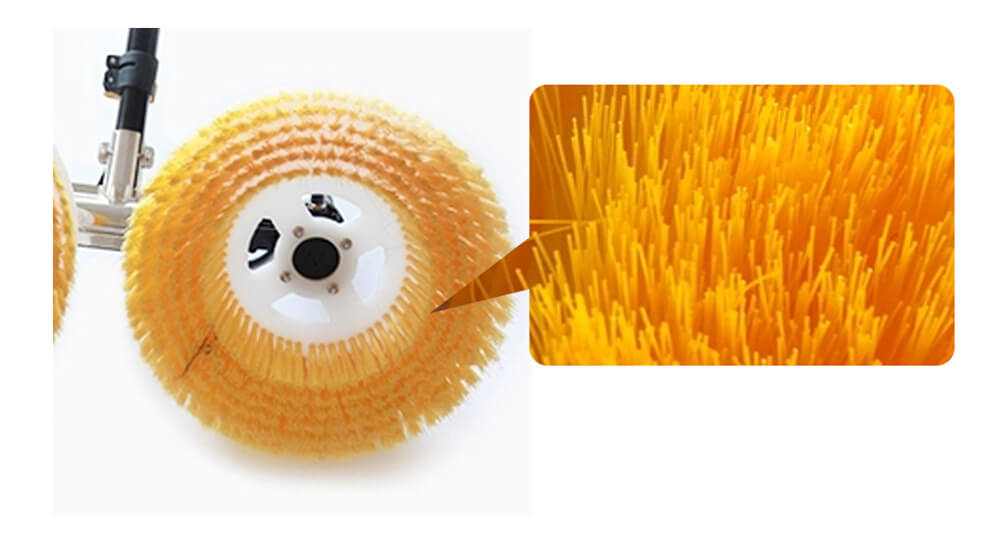

Bristle Design

The shape and arrangement of bristles also impact cleaning efficiency. Brushes with varied bristle lengths or unique patterns can enhance their ability to reach corners and edges, where dirt often accumulates. For example, brushes with angled bristles are more effective at cleaning hard-to-reach areas, ensuring that no part of the panel is overlooked.

Furthermore, the density of the bristles can affect debris removal. Densely packed bristles trap and lift dirt more effectively, while sparsely packed designs may require more effort and time to achieve similar results. The right design can optimize the cleaning process, making it quicker and more efficient.

Durability

The durability of bristles directly influences the lifespan of the cleaning brush. High-quality materials that resist wear and tear are essential for ensuring that brushes last through numerous cleaning sessions. Regular inspection for signs of fraying or damage is crucial for maintaining effectiveness.

Investing in durable bristles can reduce the frequency of replacements, leading to cost savings over time. Users should look for brushes specifically designed for prolonged use, with bristles that can withstand the rigors of regular cleaning.

Environmental Impact

As sustainability becomes a priority, the use of environmentally friendly materials in brush production is gaining traction. Brushes made from recyclable or biodegradable materials help reduce the environmental impact of cleaning processes.

Using eco-friendly bristle materials aligns with the values of many solar energy users, who often prioritize reducing their carbon footprint. Choosing sustainable cleaning options not only benefits the planet but also appeals to the growing market of environmentally conscious consumers.

Cleaning Effectiveness

Different bristle designs can yield varying cleaning results. Practical comparisons of brush performance in real-world scenarios reveal that certain designs excel in specific conditions. For example, brushes with a combination of soft and stiff bristles may provide versatility for different types of dirt.

User feedback and testing can offer valuable insights into which brush designs consistently deliver superior results. This information can guide consumers in selecting the most effective cleaning tools for their solar panels.

Maintenance and Cleaning

To ensure that bristles maintain their cleaning performance, proper maintenance is necessary. After each use, users should rinse the brush thoroughly to remove any accumulated dirt or debris. This prevents buildup that could hinder performance in future cleanings.

Additionally, storing brushes in a dry environment can prevent mold growth, particularly for natural fiber brushes. Regular inspections for wear and tear will help identify the need for replacements before significant degradation occurs.

By understanding these critical aspects of bristle quality, solar panel owners can make informed decisions about their cleaning brushes, ensuring optimal maintenance and performance of their solar energy systems.

Bristle Quality in Action

To illustrate the significance of bristle quality, let's consider practical scenarios. In a solar installation located in a dusty environment, the use of a brush with dense nylon bristles would likely yield superior results. The nylon's durability allows it to withstand repeated scrubbing, effectively removing fine dust particles that can accumulate and block sunlight. In contrast, a softer brush made from natural fibers may struggle to achieve the same level of cleanliness, requiring more frequent cleaning sessions.

In contrast, installations near trees or wildlife may benefit from a brush that combines soft and hard bristles. The soft bristles can gently clean the panel surface, while the harder bristles tackle tougher residues like bird droppings or tree sap without risking scratches. This versatility ensures that all types of debris can be effectively addressed, prolonging the life of the solar panels.

Innovations in Bristle Technology

As the solar industry evolves, innovations in brush technology are emerging. Some manufacturers are experimenting with hybrid materials that combine the benefits of different bristle types. For instance, a brush featuring a core of stiff polypropylene surrounded by softer nylon bristles can offer a balanced cleaning experience—providing both strength and gentleness.

Moreover, the introduction of smart technology in cleaning solutions is becoming more prevalent. Some modern cleaning brushes now include features like integrated sensors that detect dirt levels on the solar panels, prompting users when a cleaning is necessary. This technology not only enhances efficiency but also helps users make informed decisions about when and how to clean their panels.

User Education and Best Practices

To maximize the effectiveness of solar panel cleaning brushes, user education is essential. Providing users with clear guidelines on selecting the right brush, understanding bristle properties, and employing best cleaning practices can lead to better maintenance outcomes.

For instance, users should be educated on the importance of avoiding harsh chemicals that can degrade bristle materials or damage solar panel coatings. Instead, recommending eco-friendly cleaning solutions can ensure both effective cleaning and environmental responsibility.

Additionally, instructional materials or videos can demonstrate proper cleaning techniques, highlighting how to effectively use the brush to avoid unnecessary wear and tear on both the brush and the solar panels. This kind of education empowers users to take ownership of their solar panel maintenance.

FAQs