4s 12v 150a Smart Bms for Lifepo4 Battery Pack

Lithium-ion Battery Fundamentals: Chemistry, Structure, and Characteristics

Lithium-ion batteries are a type of rechargeable battery that has become ubiquitous in modern electronics and portable devices, from smartphones and laptops to electric vehicles and grid-scale energy storage systems. They are highly preferred over other battery chemistries due to their high energy density, longer cycle life, and relatively low self-discharge rate. The basic principle behind a lithium-ion battery is that during discharge, lithium ions move from the negative electrode (anode) to the positive electrode (cathode) through an electrolyte, while during charging, the reverse process occurs. This reversible reaction is possible due to the unique properties of lithium as a highly reactive and lightweight element.

The structure of a lithium-ion battery is composed of several key components, including the anode, cathode, separator, and electrolyte. The anode is typically made of graphite or other carbon-based materials, while the cathode is made of lithium metal oxides such as lithium cobalt oxide, lithium manganese oxide, or lithium iron phosphate. The separator is a thin, porous material that keeps the anode and cathode apart while allowing the flow of ions between them. The electrolyte is a liquid or gel substance that facilitates the movement of lithium ions between the electrodes. The combination of these components determines the performance and characteristics of a lithium-ion battery, such as capacity, voltage, energy density, and power density.

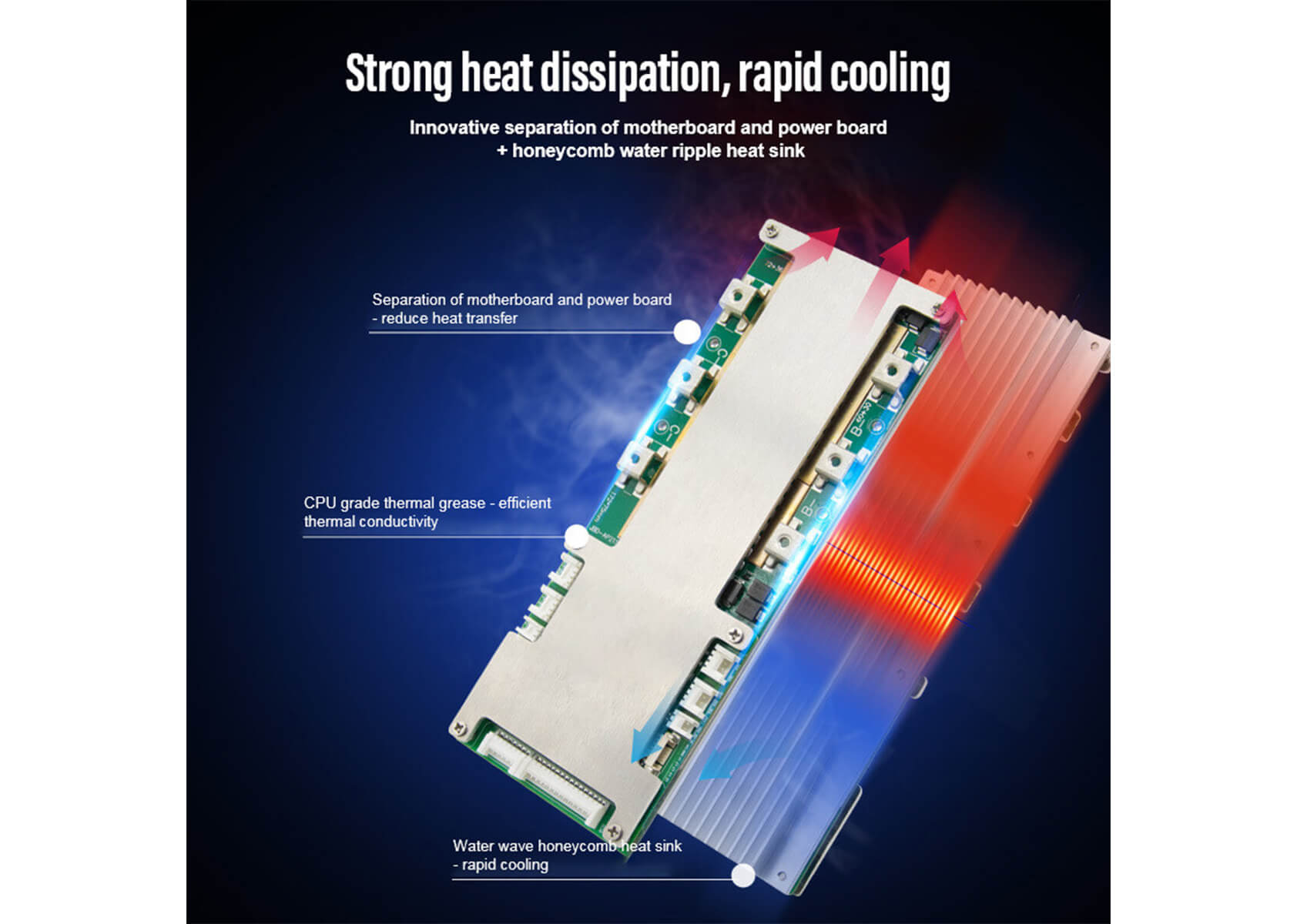

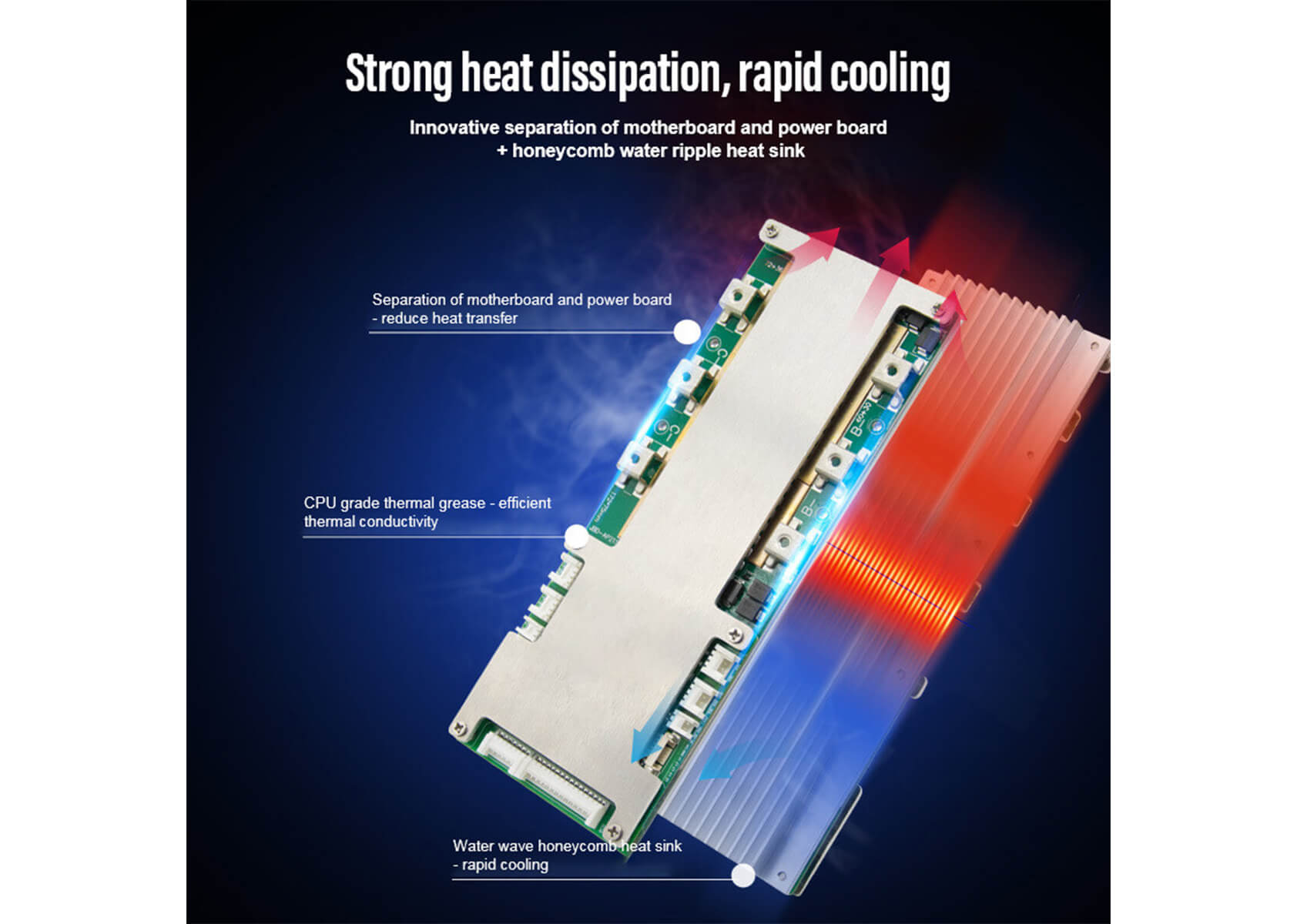

Strong heat dissipation, rapid cooling

Components of an Intelligent BMS: Sensors, Controllers, and Algorithms

An intelligent battery management system (BMS) is a crucial component in ensuring the safe, efficient, and reliable operation of a lithium-ion battery pack. The BMS consists of three main components: sensors, controllers, and algorithms. The sensors in an intelligent BMS monitor critical parameters such as battery voltage, current, temperature, and state of charge. These sensors are typically placed at various locations throughout the battery pack to capture real-time data on the state of the individual cells and the overall pack. The data from these sensors is fed into the BMS controller, which then processes the data and makes decisions on how to manage the battery.

The controller in an intelligent BMS is responsible for analyzing the data from the sensors and issuing commands to the battery pack to optimize its performance. The controller typically consists of a microprocessor, memory, and communication interfaces. It runs sophisticated algorithms that enable it to balance the individual cells in the battery pack, protect against overcharging and over-discharging, and control the charging and discharging rates to ensure the battery's safety and longevity. Finally, the algorithms used in an intelligent BMS are critical to its effectiveness. These algorithms are responsible for the estimation of the battery's state of charge and state of health, which are essential for the safe and efficient operation of the battery. They also perform cell balancing to ensure that the individual cells in the pack are charged and discharged evenly, maximizing the battery's capacity and lifespan.

Charging double protection - safety plus

Advanced Features of Intelligent BMS: State-of-Charge Estimation, Cell Balancing, and Thermal Management

Advanced features in an intelligent battery management system (BMS) are critical to maximizing the performance, safety, and lifespan of a lithium-ion battery pack. State-of-charge (SOC) estimation is one such feature that enables the BMS to accurately determine the amount of charge remaining in the battery. This estimation is essential for maximizing the battery's capacity, preventing overcharging or over-discharging, and extending its lifespan. SOC estimation algorithms use a variety of techniques, including voltage measurements, current measurements, and coulomb counting, to accurately determine the battery's charge state.

Another advanced feature of an intelligent BMS is cell balancing, which is essential for ensuring that the individual cells in a battery pack are charged and discharged evenly. Cell balancing algorithms use different techniques to equalize the voltages of the individual cells, such as active and passive balancing. Active balancing involves transferring charge between cells to even out their voltages, while passive balancing uses resistors to discharge the higher-voltage cells. Cell balancing is critical for preventing overcharging or over-discharging of individual cells, which can lead to premature failure of the battery pack.

Thermal management is also an essential feature of an intelligent BMS. Lithium-ion batteries generate heat during charging and discharging, and if this heat is not dissipated properly, it can damage the battery pack or even cause a safety hazard. Thermal management algorithms in the BMS control the temperature of the battery pack by regulating the charging and discharging rates, and by using cooling systems such as fans or liquid cooling. Proper thermal management ensures that the battery pack operates within safe temperature ranges, maximizing its performance and lifespan.

XIAOXIANG Electric App

Applications of Intelligent BMS: Electric Vehicles, Energy Storage Systems, and Consumer Electronics

Intelligent battery management systems (BMS) have a wide range of applications, including electric vehicles, energy storage systems, and consumer electronics. In electric vehicles, the BMS plays a critical role in ensuring the safety, reliability, and performance of the battery pack. The BMS monitors the individual cells in the battery pack and manages their charging and discharging rates to optimize their performance and prevent overcharging or over-discharging. It also performs cell balancing and thermal management to ensure that the battery pack operates within safe temperature ranges and maximizes its lifespan. The BMS in electric vehicles can also communicate with the vehicle's control system to provide information on the battery's state of charge and state of health, enabling the driver to make informed decisions on range and driving behavior.

Energy storage systems (ESS) are another important application of intelligent BMS. ESS are used to store energy from renewable sources such as solar and wind, and to provide backup power during grid outages. The BMS in an ESS is responsible for monitoring the state of the battery and managing its charging and discharging rates to maximize its performance and lifespan. It also performs cell balancing and thermal management to ensure the safe and reliable operation of the battery. The BMS in an ESS can also communicate with the power grid to provide frequency regulation and other grid services, enabling the integration of renewable energy sources into the grid.

Consumer electronics are another important application of intelligent BMS. Smartphones, laptops, and other portable devices rely on lithium-ion batteries for their power source, and the BMS in these devices is responsible for managing the battery's performance and ensuring its safety. The BMS monitors the battery's state of charge and state of health, manages its charging and discharging rates, and performs cell balancing and thermal management. This ensures that the battery operates safely and efficiently, maximizing its lifespan and performance in these consumer devices.

IMPORTED IC

Maintenance and Safety Considerations for Lithium-ion Batteries and Intelligent BMS

Maintenance and safety considerations are critical when working with lithium-ion batteries and intelligent battery management systems (BMS). Lithium-ion batteries have high energy density and are potentially dangerous if mishandled. Proper handling, storage, and maintenance are essential to ensure their safe and reliable operation. Regular inspection and testing of the batteries, including visual inspection for signs of damage or swelling, can help detect potential issues before they become a safety hazard. It is also important to follow the manufacturer's guidelines for charging and discharging the batteries and to use only approved chargers and accessories.

The intelligent BMS also plays a critical role in maintaining the safety and reliability of the battery. The BMS must be regularly tested and calibrated to ensure that it accurately monitors the battery's state of charge and state of health. It is also important to follow the manufacturer's guidelines for programming the BMS and to regularly update the firmware to ensure that it is operating correctly. Proper cell balancing and thermal management are essential for maintaining the safety and reliability of the battery pack, and these features should be regularly tested and calibrated as well. By following proper maintenance and safety procedures, lithium-ion batteries and intelligent BMS can be used safely and reliably in a wide range of applications.