Contents:

When working with lithium batteries, one common challenge is connecting batteries of different amp-hour (Ah) capacities. This requires careful planning to ensure the safety and efficiency of the system. Below, we’ll explore the steps to connect lithium batteries with varying capacities, the potential configurations, and best practices.

Understanding Lithium Battery Configurations

There are two primary ways to connect batteries:

1. Series Connection

Increases the voltage while keeping the capacity (Ah) the same. For example, connecting two 12V batteries in series results in a 24V system with the same Ah rating as the lowest battery in the series.

2. Parallel Connection

Increases the capacity (Ah) while maintaining the same voltage. For instance, two 12V batteries connected in parallel will remain 12V but combine their Ah capacities.

Connecting Batteries of Different Amp-Hour Capacities

Mixing lithium batteries with different Ah ratings can be problematic if not done correctly. Here's how you can manage such a connection safely:

1. Match Voltage Ratings

- Ensure that all batteries have the same nominal voltage (e.g., 12V). Mismatched voltages can lead to overcharging or undercharging, damaging the batteries.

2. Choose the Connection Type

- Parallel Connection: This is the most suitable method when combining batteries with different Ah capacities. In this setup, the total capacity becomes the sum of the individual capacities.

- Series Connection: Avoid using batteries with varying Ah ratings in series, as the lower-capacity battery may discharge or charge faster, potentially causing imbalance or damage.

3. Use a Battery Management System (BMS)

- A high-quality BMS can help monitor and regulate the charging and discharging of individual batteries. This is particularly critical for batteries of different capacities.

4. Consider Balancing Circuits

- Incorporate balancing circuits or devices to ensure that all batteries charge and discharge evenly.

5. Monitor the System Regularly

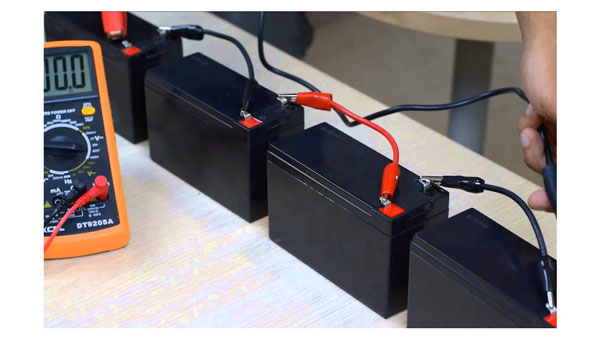

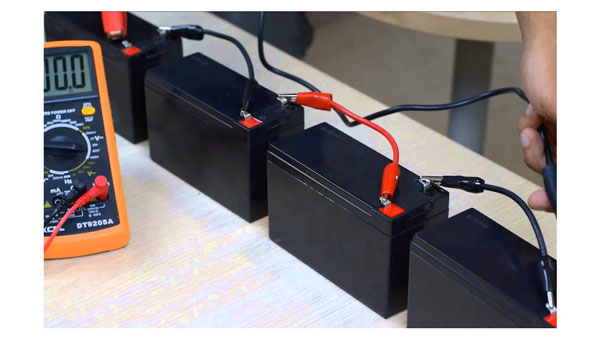

- Install voltage and current meters to monitor the system's performance. Check for any signs of overcharging, overheating, or imbalance.

Example Table for Connecting Batteries

Below is a visual representation of connecting lithium batteries with different Ah ratings in parallel.

| Battery |

Voltage (V) |

Capacity (Ah) |

Notes |

| Battery 1 |

12 |

100 |

Higher capacity |

| Battery 2 |

12 |

80 |

Lower capacity |

| Battery 3 |

12 |

120 |

Use with caution |

Best Practices

-

Avoid Draining Batteries Fully: Deep discharges can harm lower-capacity batteries.

-

Keep Batteries at Similar Charge Levels: Charge all batteries fully before connecting them.

-

Use Identical Batteries When Possible: While connecting different capacities is feasible, it's always better to use batteries of the same specifications for optimal performance and longevity.

By following these guidelines, you can safely connect lithium batteries of different amp-hour ratings to create a functional and efficient energy storage system.

Charging and Discharging Lithium Batteries with Different Amp-Hour Capacities

Proper management of charging and discharging is critical when connecting lithium batteries with varying capacities. Uneven usage can lead to imbalances, reducing the overall lifespan of the battery system. Below are some detailed strategies to handle charging and discharging effectively:

Charging Tips

1. Use a Compatible Charger

- Choose a charger designed for lithium batteries with matching voltage and current ratings.

2. Charge Batteries Individually First

- Before connecting batteries in parallel, charge each battery separately to ensure they start at similar voltage levels.

3. Monitor Charging Voltage

- Use a smart charger or a BMS to maintain voltage within the safe range (e.g., 3.2–3.65V per cell for LiFePO4 batteries).

Discharging Tips

1. Avoid Overdischarging

- Set a cutoff voltage in the BMS to prevent batteries from dropping below their minimum voltage, typically around 2.5V per cell.

2. Balance Current Draw

- Batteries with higher capacities will naturally supply more current in parallel configurations. Ensure this does not overload smaller-capacity batteries.

Visualizing Battery Performance

Charging and discharging curves of lithium batteries with different amp-hour capacities.

Precautions When Connecting Lithium Batteries

1. Test the Configuration

- After connecting, test the system under load to identify any anomalies.

2. Inspect Connections Regularly

- Check for loose or corroded terminals, as these can lead to resistance and heat generation.

3. Avoid Extreme Temperatures

- Lithium batteries perform best between 10°C and 45°C. Use thermal management solutions if necessary.

4. Plan for Maintenance

- Implement a regular schedule to inspect and recalibrate the system, ensuring all batteries perform optimally.

Selecting Components for Your Lithium Battery System

When connecting lithium batteries with different amp-hour capacities, the supporting components are as important as the batteries themselves. Proper selection of cables, connectors, and other accessories can enhance system reliability and performance.

Choosing Cables and Connectors

1. Cable Thickness (AWG)

- Use cables with adequate thickness to handle the maximum current without excessive resistance or heat buildup. The appropriate cable gauge depends on the total system load and distance between components.

2. High-Quality Connectors

- Opt for connectors rated for the system's voltage and current to ensure a stable connection. Anderson Powerpole or similar connectors are often used in such setups.

3. Cable Length

- Keep cables as short as possible to minimize voltage drop and resistance.

Using Fuses and Circuit Breakers

1. Install Fuses for Each Battery

- Place a fuse on the positive terminal of each battery to protect against overcurrent conditions.

2. Use Circuit Breakers

- Incorporate a main circuit breaker to protect the entire system during faults.

Compatibility Table for Lithium Battery Systems

The following table provides a compatibility chart for lithium batteries with different amp-hour ratings.

| Component |

Recommended Rating |

Purpose |

Notes |

| Battery Cable |

4 AWG or thicker |

Connect batteries |

Adjust based on load |

| Connector |

Anderson Powerpole |

Ensure secure connection |

Rated for high current |

| Fuse |

100A-200A |

Overcurrent protection |

Match system current |

| Circuit Breaker |

150A |

Main system protection |

Resettable preferred |

Troubleshooting Common Issues in Mixed Amp-Hour Systems

1. Voltage Imbalance

- Regularly monitor individual battery voltages to detect discrepancies early.

2. Uneven Charging/Discharging

- Use a BMS with cell-balancing features to mitigate this issue.

3. Heat Generation

- Ensure adequate ventilation and proper cable sizing to prevent overheating during operation.

4. Performance Degradation

- Periodically measure each battery’s capacity to identify and replace degraded units.

Maintaining and Extending Battery Lifespan

To ensure the longevity and reliability of your lithium battery system, maintenance is key. Lithium batteries are known for their durability, but improper handling can significantly shorten their lifespan. Below are some best practices for maintenance:

1. Perform Regular Inspections

- Periodically check all connections, cables, and terminals for wear, corrosion, or loosening. Address any issues immediately to avoid resistance buildup or short circuits.

2. Monitor Battery Health

- Use diagnostic tools or the BMS to track individual battery performance, such as charge cycles, capacity, and internal resistance. Replace degraded batteries promptly to maintain system balance.

3. Keep Batteries Clean and Dry

- Protect the batteries from dust, moisture, and extreme weather conditions by housing them in a clean, temperature-controlled environment.

Building a Reliable and Efficient System

Connecting lithium batteries with different amp-hour capacities requires careful planning, the right tools, and consistent maintenance. By understanding the principles of battery configurations, using quality components, and adhering to best practices, you can create a system that is both safe and efficient. Whether powering a small off-grid setup or a large renewable energy solution, thoughtful design and proactive management will ensure your system performs reliably and serves your energy needs effectively over time.

FAQs

Yes, you can connect them in series, but it’s not recommended because batteries with lower capacities may discharge faster and be damaged. Use a battery management system (BMS) to monitor and balance the cells.

In parallel, batteries will balance themselves to share the load proportionally to their capacities. However, ensure they have the same voltage and are fully charged before connecting.

Yes, a BMS is crucial for safety and performance. It monitors voltage, temperature, and current, ensuring balanced charging and discharging across all batteries.

Charge each battery to its full voltage individually using a compatible charger. This ensures they start at the same voltage, minimizing imbalance issues after connection.

Yes, they can be charged together if connected in parallel and managed by a BMS. The charging current will be distributed proportionally to the capacities of the batteries.