1. Understanding the differences between LiFePO4 and other battery chemistries

LiFePO4 (Lithium Iron Phosphate) is a type of lithium-ion battery chemistry that offers several advantages over other types of lithium-ion batteries, such as LiPo (Lithium Polymer) and Li-ion (Lithium Ion). Some of the key differences include:

- Safety: LiFePO4 batteries are considered safer than other lithium-ion batteries because they are less prone to thermal runaway and do not catch fire or explode as easily. This is because LiFePO4 has a higher thermal runaway temperature than other lithium-ion chemistries.

- Longevity: LiFePO4 batteries have a longer lifespan compared to other lithium-ion batteries. They can handle more charging cycles and are less prone to degradation over time.

- Performance: LiFePO4 batteries have a lower energy density compared to other lithium-ion batteries, which means they have a lower capacity per unit of weight or volume. However, they have a higher power density, which means they can deliver higher current output for a given weight or volume.

- Cost: LiFePO4 batteries are typically more expensive than other lithium-ion batteries, but their longer lifespan and improved safety make them a cost-effective option in the long run.

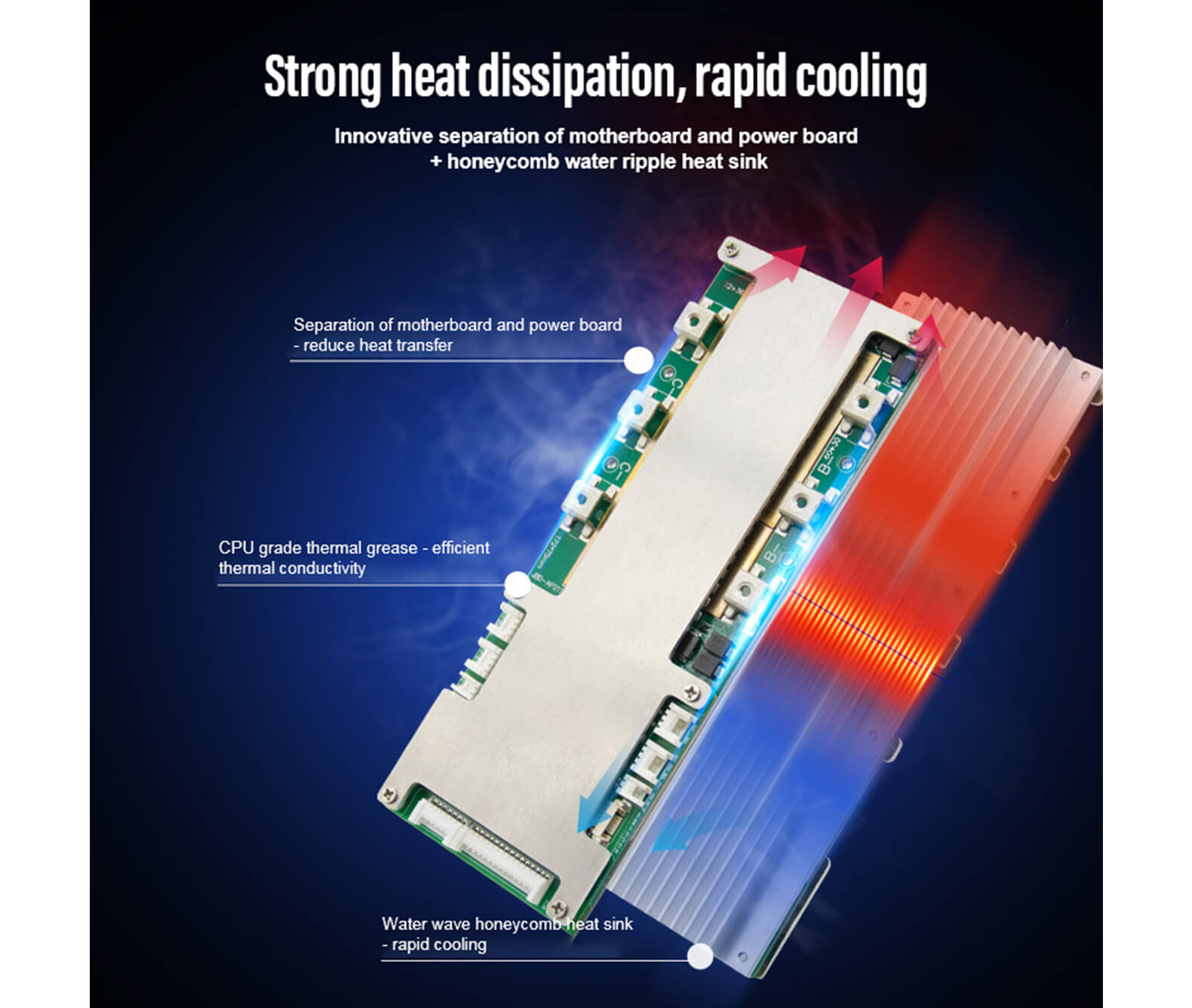

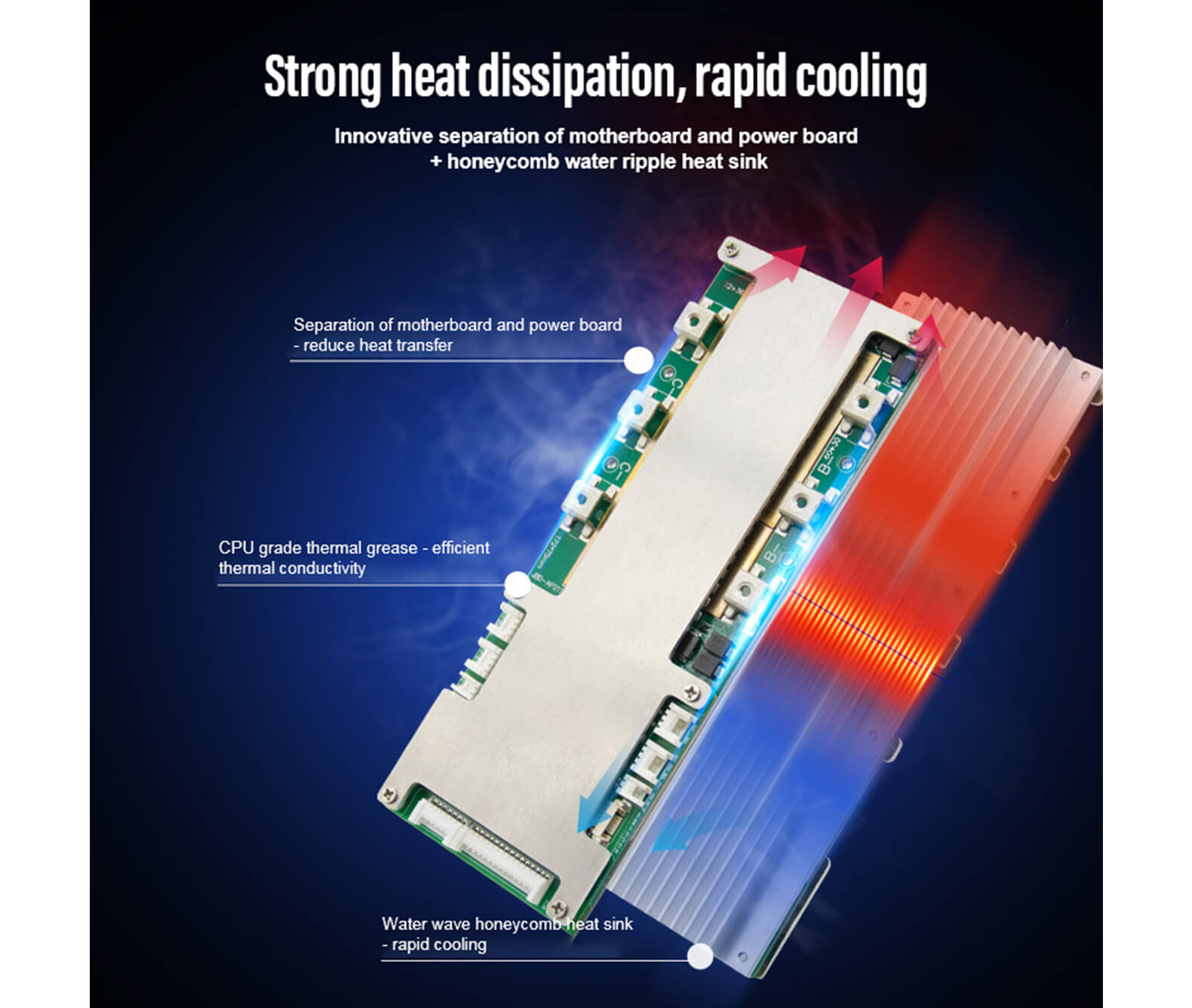

BMS protection board

2. Selecting a suitable BMS protection board for LiFePO4 battery pack

Selecting the right BMS protection board is crucial for the proper operation and safety of LiFePO4 battery packs. When choosing a BMS protection board, it is important to consider several key factors such as voltage, capacity, number of cells, features, and quality. LiFePO4 batteries have a nominal voltage of 3.2V per cell, which is lower than other lithium-ion chemistries. Therefore, it is important to choose a BMS protection board that is compatible with this voltage range to prevent overcharging or undercharging of the battery pack.

Capacity is another important consideration when selecting a BMS protection board for LiFePO4 battery packs. It is essential to choose a board that can handle the capacity of the battery pack and has a suitable maximum current rating and discharge rate. Choosing a board that is not able to handle the capacity of the battery pack can result in reduced performance and safety risks.

It is important to select a BMS protection board from a reputable manufacturer with a proven track record of reliability and safety. Choosing a board from an unknown or low-quality manufacturer can result in safety risks, such as overcharging or thermal runaway. Additionally, choosing a board from a reputable manufacturer ensures that you will have access to technical support and resources in case of any issues. Overall, selecting the right BMS protection board for LiFePO4 battery packs requires careful consideration of several key factors to ensure optimal performance and safety.

3. Configuring the BMS protection board for LiFePO4 battery pack

Configuring a BMS protection board for LiFePO4 battery packs is an important step to ensure optimal performance and safety. The specific configuration steps will vary depending on the particular board and battery pack you are using, but there are some general guidelines to follow. One key aspect of configuring a BMS protection board for LiFePO4 battery packs is setting the overcharge and over-discharge voltage limits. LiFePO4 batteries are less tolerant to overcharging and over-discharging compared to other lithium-ion chemistries, so it is important to set these limits to prevent damage to the battery pack. Most BMS protection boards will have configurable settings for these limits, and it is important to set them within the safe operating range of the battery pack.

Another important aspect of configuring a BMS protection board for LiFePO4 battery packs is setting the balance charging function. LiFePO4 battery packs require a balance charging function to ensure that each cell in the pack is charged to the same voltage level. This is important to prevent cell imbalances, which can reduce the performance and lifespan of the battery pack. Most BMS protection boards will have a balance charging function, and it is important to configure it correctly based on the number of cells in your battery pack.

It is also important to ensure that the BMS protection board is properly connected to the battery pack and other components, such as the charging circuit and load circuit. Check the manufacturer's instructions or user manual to ensure that the connections are made correctly and that the board is properly calibrated. It is also important to periodically check and test the BMS protection board to ensure that it is functioning correctly and to troubleshoot any issues that may arise. Overall, configuring a BMS protection board for LiFePO4 battery packs requires careful attention to detail and adherence to manufacturer guidelines to ensure optimal performance and safety.

4. Testing the BMS protection board for LiFePO4 battery pack

Testing BMS protection boards for LiFePO4 battery packs is an essential step in ensuring the safety and proper function of the battery system. The specific testing procedures will vary depending on the particular board and battery pack you are using, but there are some general guidelines to follow. One key aspect of testing a BMS protection board is to verify that it is properly configured and calibrated. This involves checking that the overcharge and over-discharge voltage limits, as well as the balance charging function, are set correctly based on the number of cells in the battery pack. It is also important to verify that the board is properly connected to the battery pack and other components.

Another important aspect of testing a BMS protection board is to verify that it can detect and respond to overcharge, over-discharge, and short-circuit conditions. This involves intentionally creating these conditions and verifying that the board responds appropriately by disconnecting the battery pack or activating other safety mechanisms. It is important to do this testing in a controlled environment with appropriate safety measures in place.

It is important to periodically test the BMS protection board over the lifespan of the battery pack to ensure that it continues to function properly. This can involve testing the voltage limits, balance charging function, and safety mechanisms under different operating conditions and loads. It is important to follow the manufacturer's guidelines and recommendations for testing and maintenance to ensure optimal performance and safety of the battery system. Overall, testing BMS protection boards for LiFePO4 battery packs requires careful attention to detail and adherence to safety protocols to ensure optimal performance and safety.

LiFePO4 battery pack

5. Troubleshooting common issues with BMS protection board for LiFePO4 battery pack

Despite proper configuration and testing, issues can arise with BMS protection boards for LiFePO4 battery packs. Common troubleshooting steps can help identify and resolve these issues. One common issue is a voltage reading that is higher or lower than expected. This can be caused by a malfunctioning sensor or calibration issue. To troubleshoot this issue, it is important to check the connections and calibration of the sensor and verify that the voltage reading is accurate using a multimeter. If the voltage reading is still incorrect, it may be necessary to replace the sensor or recalibrate the BMS protection board.

Another common issue is an inability to charge the battery pack or a sudden drop in capacity. This can be caused by a faulty balance charging function, a damaged cell, or a malfunctioning circuit. To troubleshoot this issue, it is important to verify that the balance charging function is properly configured and that each cell is being charged to the same voltage level. It is also important to check each cell for damage or signs of degradation. If no issues are found with the balance charging or cells, it may be necessary to check the circuitry and wiring for any damage or loose connections. Replacing any damaged components or re-wiring the circuit may be necessary to resolve this issue.