High Conversion Solar Panels

- Material Composition and Appearance

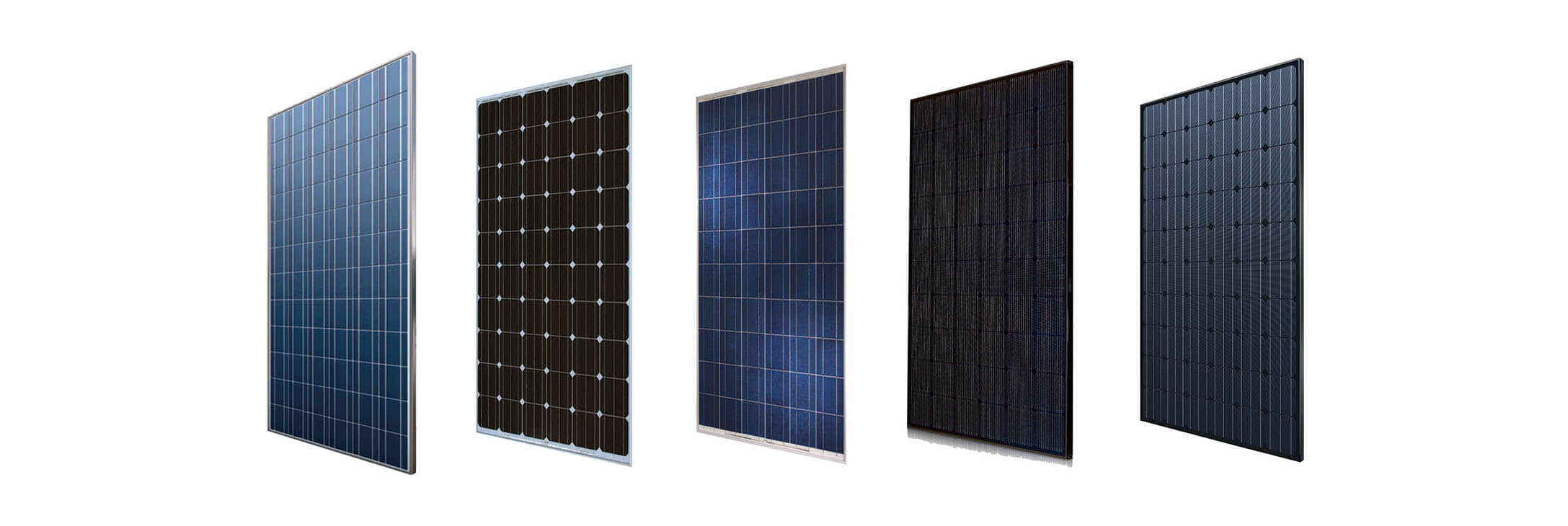

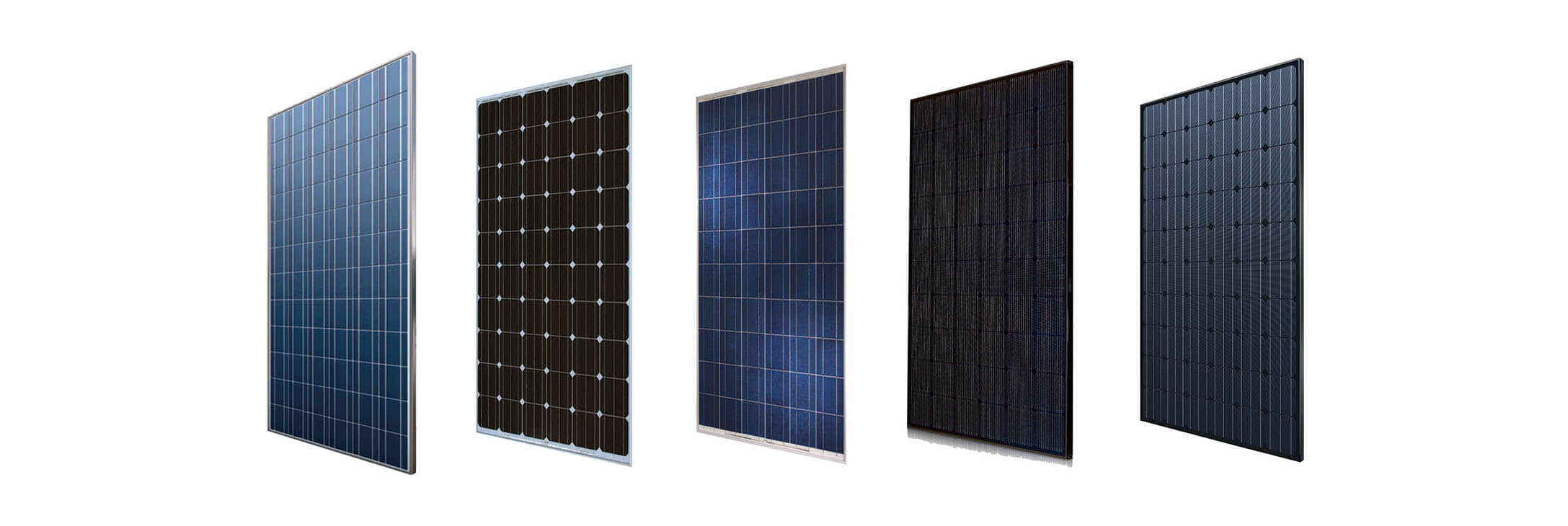

Solar panels are a vital component in the growing renewable energy industry, with their ability to harness the power of the sun and convert it into electricity. The two main types of solar panels used in this industry are monocrystalline and polycrystalline panels. The material composition and appearance of these panels are important factors to consider when choosing the best option for your energy needs.

Monocrystalline solar panels are made from a single, pure silicon crystal. The manufacturing process for these panels involves growing a single silicon crystal and then slicing it into thin wafers, which are then used to make the solar cells. The result is a uniform, black-colored solar panel with a sleek and modern appearance. This uniformity not only gives the panels an aesthetically pleasing look, but it also contributes to their efficiency and performance. The single crystal structure allows electrons to move more freely, resulting in higher efficiency levels than polycrystalline panels.

Polycrystalline solar panels, on the other hand, are made from multiple silicon fragments melted together. This manufacturing process is less expensive than the process used for monocrystalline panels, making polycrystalline panels a more cost-effective option. However, the multiple fragments create a grainy, blue-ish appearance that is less uniform than the sleek appearance of monocrystalline panels. The lower purity level of the silicon used in polycrystalline panels also results in lower efficiency levels compared to monocrystalline panels.

The material composition and appearance of monocrystalline and polycrystalline solar panels are important factors to consider when choosing the best option for your energy needs. Monocrystalline panels are made from a single, pure silicon crystal, resulting in a uniform, black-colored panel that is both aesthetically pleasing and efficient. Polycrystalline panels, on the other hand, are made from multiple silicon fragments melted together, resulting in a less uniform, blue-ish colored panel that is less efficient but more cost-effective. Ultimately, the choice between the two types of panels will depend on your specific energy needs and budget.

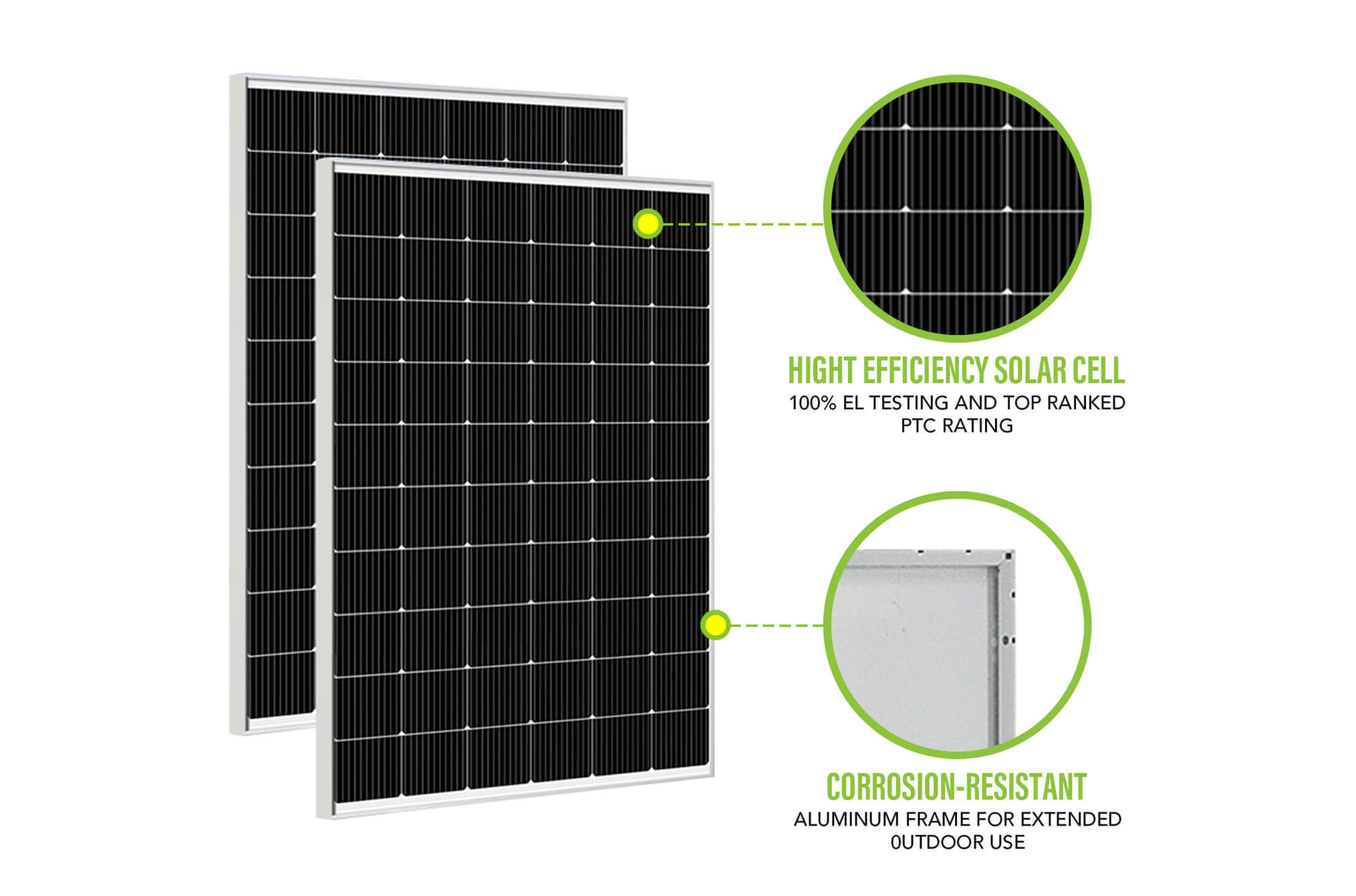

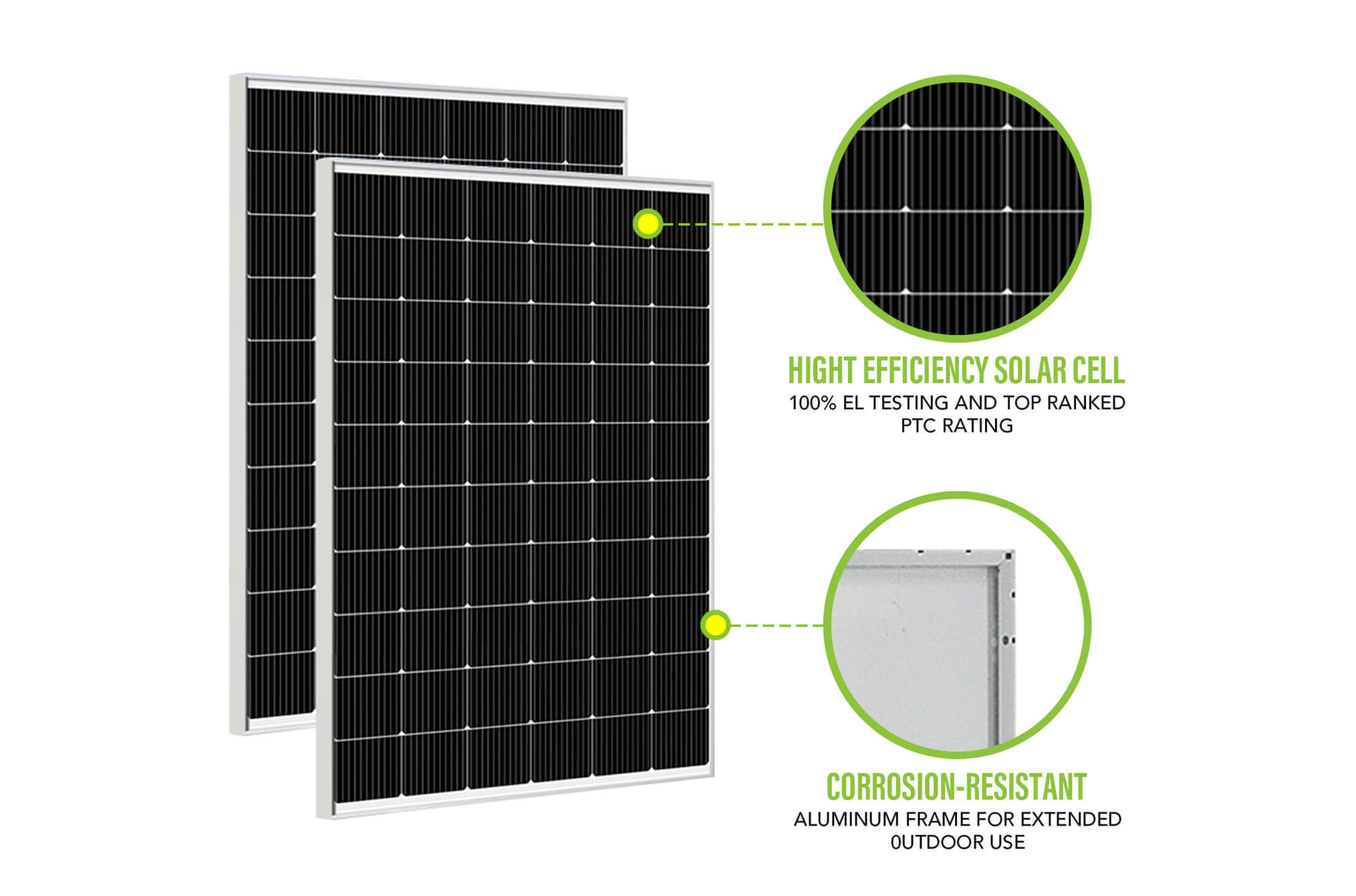

Half-Cut Mono Solar Panels

- Efficiency and Performance

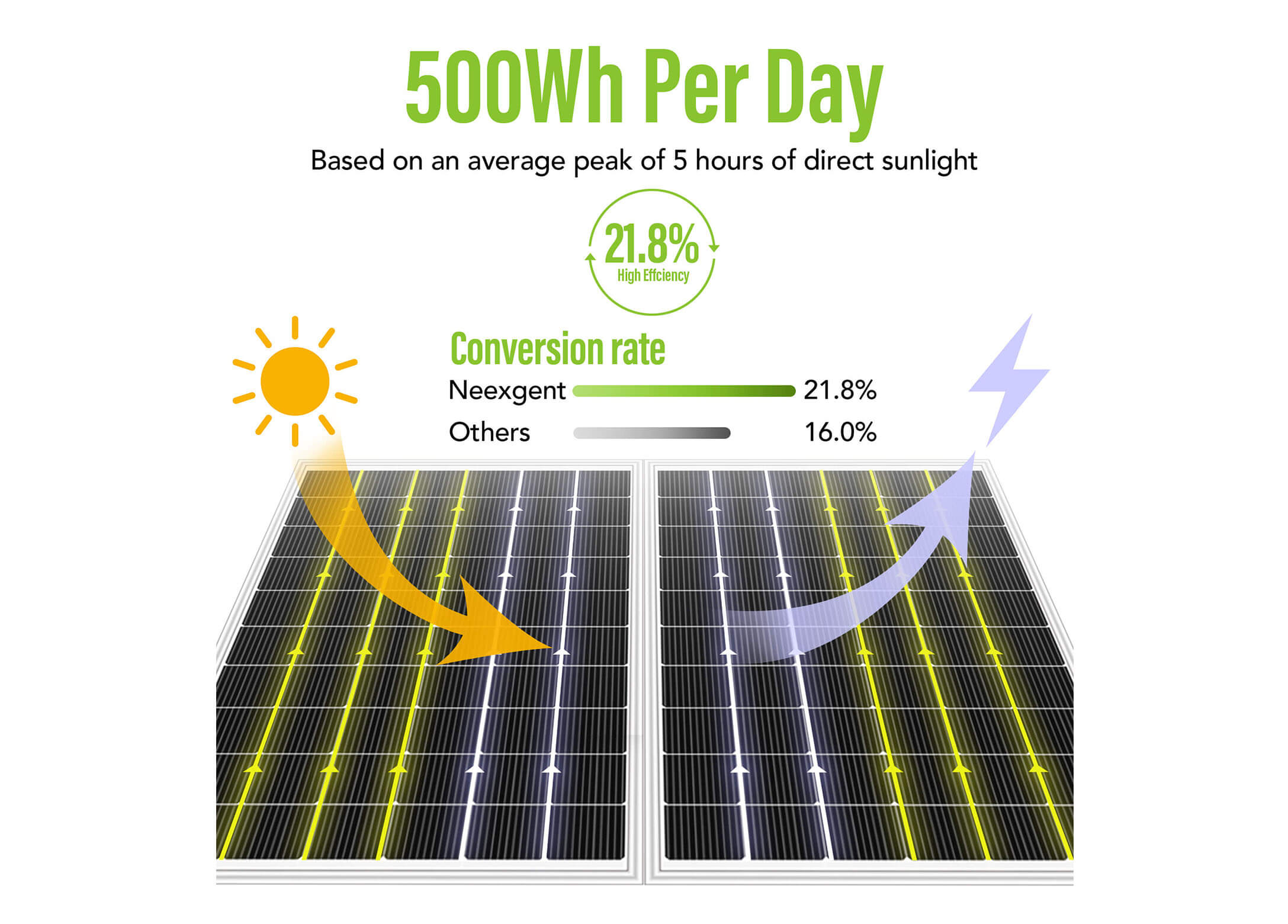

Efficiency and performance are important considerations when choosing between monocrystalline and polycrystalline solar panels. Both types of panels can generate electricity from sunlight, but their efficiency and performance levels can vary due to differences in their material composition and manufacturing processes.

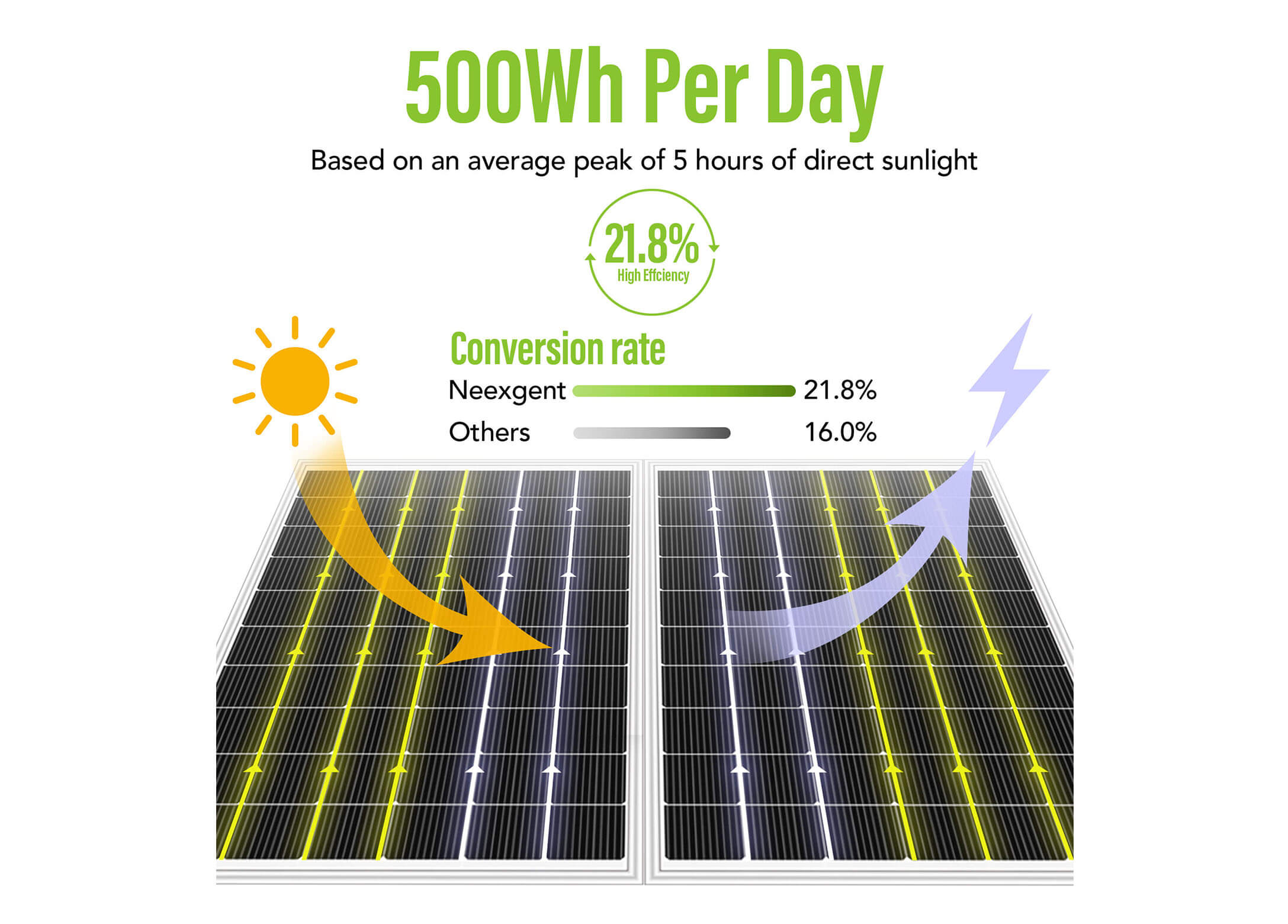

Monocrystalline solar panels are known for their high efficiency levels due to their single crystal structure. The electrons in a single crystal can move more freely, which leads to better electron flow and higher efficiency levels. Monocrystalline panels can achieve efficiencies of up to 22%, making them a popular choice for those looking for maximum output from their solar panels.

Polycrystalline solar panels are typically less efficient than monocrystalline panels due to their manufacturing process. The multiple fragments of silicon used in their production can lead to lower electron mobility and a decrease in overall efficiency. However, polycrystalline panels have seen significant improvements in recent years and can now achieve efficiencies of up to 19%. They are also a more cost-effective option, making them a popular choice for those looking for a balance between cost and efficiency.

The efficiency and performance of solar panels are important factors to consider when choosing the best option for your energy needs. Monocrystalline panels are known for their high efficiency levels, while polycrystalline panels offer a more cost-effective option with a slightly lower efficiency level. The choice between the two types of panels will depend on your specific energy needs and budget.

- Manufacturing Process and Cost

The manufacturing process and cost of monocrystalline and polycrystalline solar panels are important considerations when deciding which type of panel to use. The process used to manufacture the panels can affect their quality, efficiency, and overall cost.

Monocrystalline solar panels are made from a single, high-purity silicon crystal. The process involves growing a single crystal and then slicing it into thin wafers, which are then used to create the solar cells. This process is more complex and time-consuming than the manufacturing process for polycrystalline panels, which can result in higher costs. However, the single crystal structure of monocrystalline panels can lead to higher efficiency levels, making them a cost-effective choice over the long term.

Polycrystalline solar panels are made from melted fragments of silicon. The silicon is melted down and poured into a mold to create the solar cells. This manufacturing process is less expensive than the process used for monocrystalline panels, resulting in a lower cost per panel. However, the lower purity level of the silicon used in polycrystalline panels can lead to lower efficiency levels, which can affect their long-term cost-effectiveness.

- Environmental Impact and Sustainability

Environmental impact and sustainability are important considerations when choosing between monocrystalline and polycrystalline solar panels. The manufacturing process and materials used can have a significant impact on the environment and their long-term sustainability.

Monocrystalline solar panels are made from high-purity silicon, which is mined from the earth. The mining process can have a significant impact on the environment, including deforestation, soil erosion, and habitat destruction. However, some manufacturers have taken steps to reduce their environmental impact by using recycled silicon or implementing sustainable mining practices.

Polycrystalline solar panels are typically made from lower-purity silicon, which requires less energy to produce than the high-purity silicon used in monocrystalline panels. This can lead to a lower carbon footprint and reduced environmental impact. However, the manufacturing process still requires the use of energy and resources, which can impact the environment.

In terms of sustainability, both types of solar panels have a long lifespan and can provide clean energy for many years. However, the materials used in the manufacturing process can affect their overall sustainability. Some manufacturers have taken steps to improve sustainability, such as using recycled materials, implementing sustainable practices, and offering recycling programs for end-of-life solar panels.

The environmental impact and sustainability of solar panels are important factors to consider when choosing the best option for your energy needs. Monocrystalline panels can have a significant environmental impact due to the mining of high-purity silicon, but some manufacturers have taken steps to reduce their impact. Polycrystalline panels typically have a lower environmental impact, but their manufacturing process still requires the use of resources. Both types of panels can provide clean energy for many years and some manufacturers are taking steps to improve their overall sustainability.