Solar panels are integral to renewable energy generation, converting sunlight into electricity using photovoltaic (PV) cells. While much attention is given to the efficiency of the photovoltaic cells themselves, the structure materials that make up the entire panel are equally crucial. These materials ensure that solar panels are durable, weather-resistant, and capable of withstanding harsh environmental conditions over their long lifespan. In this article, we will explore the key materials used in the structure of solar panels and why they are essential for the panel’s performance and longevity.

Key Structure Materials of Solar Panels

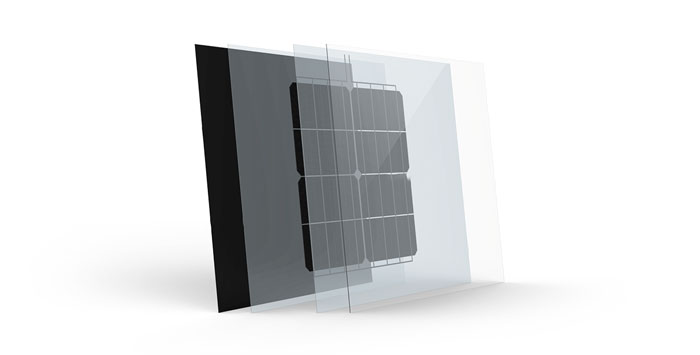

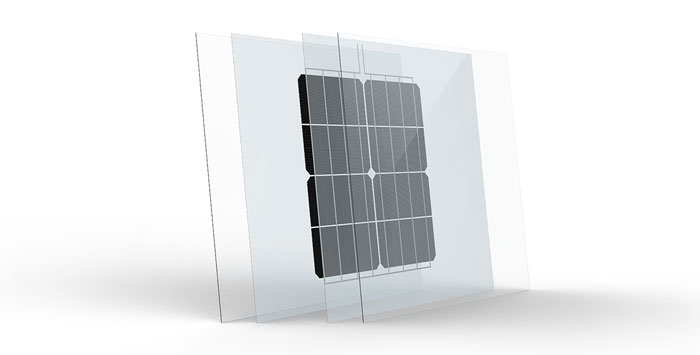

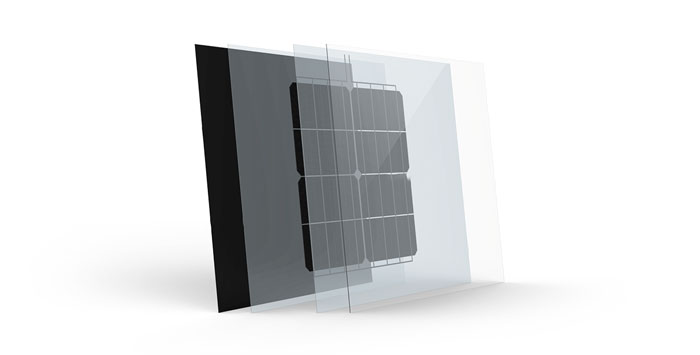

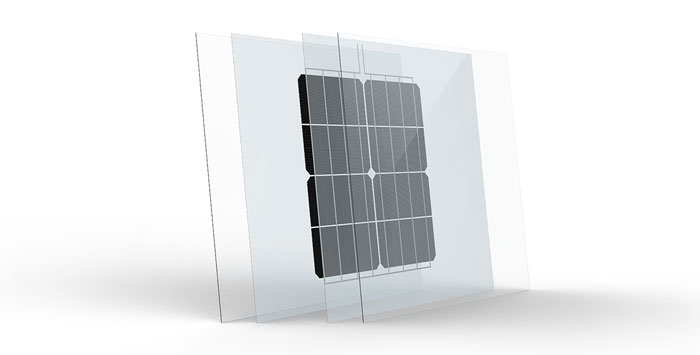

A solar panel is constructed from several layers, each serving a specific function. The materials that make up these layers are selected for their durability, protection, and role in optimizing the panel's overall performance. The main structure materials of a solar panel include the frame, glass, encapsulant, backsheet, and junction box.

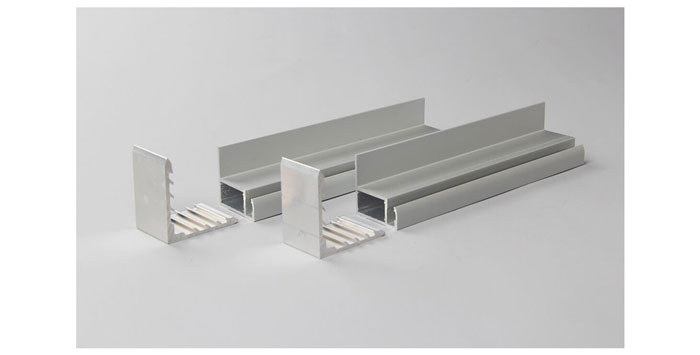

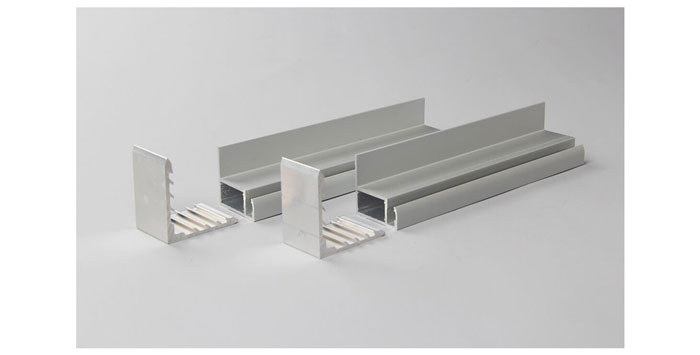

1. Aluminum Frame

The frame is the most visible and essential structural component of a solar panel. Aluminum is the most commonly used material for the frame due to its excellent properties in terms of strength, weight, and resistance to corrosion.

-

Lightweight and Strong: Aluminum is both lightweight and strong, making it easy to handle and install. The material offers a good balance of strength-to-weight ratio, allowing it to hold the solar panel securely without adding excessive weight.

-

Corrosion Resistance: Solar panels are often exposed to harsh outdoor environments, including rain, wind, and UV radiation. Aluminum naturally forms a protective oxide layer, which prevents rust and corrosion, enhancing the durability of the panel over time.

-

Cost-Effective: Aluminum is relatively inexpensive compared to other metals like stainless steel, making it a popular choice for large-scale solar installations.

Overall, aluminum frames provide the structural integrity needed to protect the photovoltaic cells while ensuring the panel remains lightweight and easy to install.

2. Glass Layer

The glass layer is one of the most important materials in solar panels. It serves as a protective covering for the photovoltaic cells while allowing sunlight to pass through efficiently. The glass is usually tempered to make it more durable and resistant to damage.

-

Tempered Glass: Solar panels require toughened glass to protect the delicate photovoltaic cells from physical impacts, such as hail or falling debris. Tempered glass is five times stronger than regular glass, which ensures the panel's longevity.

-

Transparency: The glass must be highly transparent to allow as much sunlight as possible to reach the photovoltaic cells. This ensures maximum efficiency in converting sunlight into electricity.

In addition to its protective function, the glass layer also helps maintain the panel's structural integrity by acting as a shield against environmental factors such as dirt, moisture, and UV radiation.

.jpg)

3. Encapsulant Material (EVA)

The encapsulant material, often made of ethylene-vinyl acetate (EVA), is crucial for holding the photovoltaic cells in place and protecting them from moisture and mechanical stress. It is placed between the cells and the glass, providing a cushion that ensures the cells remain secure and operational.

-

Protection from Moisture and Environmental Stress: The encapsulant ensures that the photovoltaic cells are insulated from moisture, preventing corrosion and damage. It also protects the cells from mechanical stress that might occur during the manufacturing or installation process.

-

UV Resistance: EVA is designed to be resistant to UV degradation, which helps maintain the panel’s performance over time.

By encasing the photovoltaic cells in EVA, the material enhances the panel's durability and helps preserve its efficiency.

4. Backsheet Material

The backsheet is the final layer at the rear of the solar panel. This material serves as a protective barrier, shielding the photovoltaic cells from moisture, dirt, and UV radiation. The backsheet is typically made of durable plastic materials such as polyester, polyethylene, or polyvinyl fluoride.

-

Moisture Barrier: The backsheet prevents moisture from reaching the photovoltaic cells, which is critical in preventing electrical shorts or degradation of the cells over time.

-

UV and Thermal Protection: The backsheet also provides UV protection, ensuring that sunlight does not cause deterioration of the internal components of the panel.

-

Electrical Insulation: It helps insulate the panel from electrical faults by offering an additional layer of protection.

The backsheet ensures that the solar panel remains resistant to environmental elements, extending the lifespan of the panel.

5. Junction Box

The junction box, located at the rear of the solar panel, is where all the electrical connections are made. It serves as the interface for connecting the solar panel to the rest of the solar power system.

-

Protection from Water and Dust: The junction box is typically sealed and weatherproof to prevent water or dust from entering and damaging the electrical components inside.

-

Electrical Connectivity: It houses the diodes and connectors that allow the solar panel to be integrated into a larger solar energy system.

The junction box is essential for ensuring the panel’s electrical integrity and providing a safe and reliable connection between the photovoltaic cells and the external system.

Why Are Solar Panel Structure Materials Important?

The structure materials of a solar panel serve more than just a protective role. They are designed to work in harmony to maximize the efficiency, durability, and lifespan of the solar panel.

Durability and Longevity

Solar panels are designed to last for decades, often with warranties of 20-25 years or more. The structure materials, including the aluminum frame, tempered glass, and backsheet, must be able to withstand harsh environmental conditions such as extreme temperatures, high winds, hail, and UV radiation. High-quality materials ensure that the panel will continue to operate effectively for many years, reducing the need for costly repairs or replacements.

Energy Efficiency

The materials used in the structure of the solar panel also affect its overall energy efficiency. For instance, the glass must be highly transparent to allow as much sunlight as possible to reach the photovoltaic cells. At the same time, the encapsulant material must not interfere with the light absorption capabilities of the cells. The materials must strike a delicate balance between protection and performance to ensure the panel operates at maximum efficiency.

Cost-Effectiveness

The choice of structure materials directly impacts the cost of manufacturing solar panels. Aluminum, EVA, and glass are cost-effective materials that contribute to affordable pricing while still ensuring durability and performance. As the demand for solar panels continues to grow, the use of high-quality, cost-effective materials allows manufacturers to scale production while keeping prices competitive.

.jpg)