Contents:

1. Introduction to Solar Panel Cleaning

2. Effectiveness of Cleaning

3. Time and Labor Efficiency

4. Cost Considerations

5. Water Usage and Environmental Impact

6. Scalability

7. Maintenance and Reliability

8. Safety Considerations

9. Case Studies and Real-World Applications

10. Conclusion: Which Method is Better?

FAQs

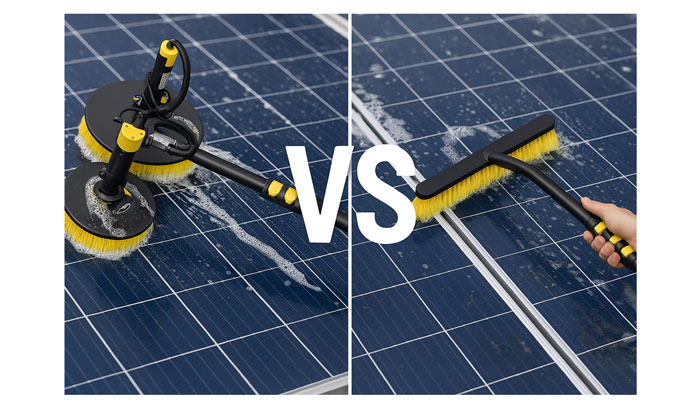

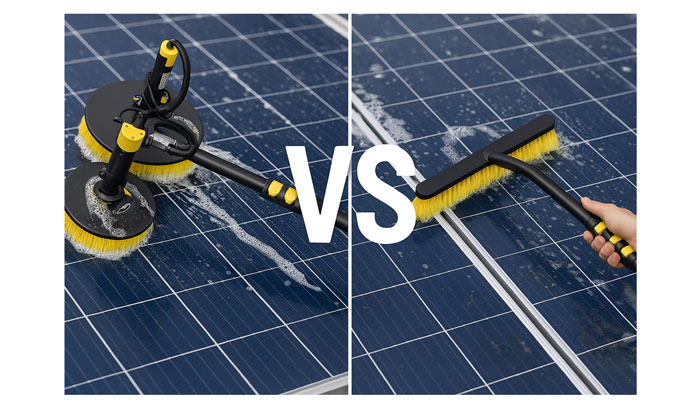

As solar energy continues to gain global traction, the importance of maintaining solar panels for optimal efficiency has become increasingly evident. Dirty or dusty panels can lead to significant energy losses—up to 30% in some cases. Whether it's a residential rooftop system or a sprawling commercial solar farm, ensuring solar panels are clean is critical. This brings us to the debate: Automated solar panel cleaning brush vs manual cleaning methods—which one is better?

This article dives deep into both approaches, comparing their effectiveness, costs, scalability, and environmental impact to help you make an informed decision.

1. Introduction to Solar Panel Cleaning

Solar panels are exposed to the elements, which means dust, bird droppings, pollen, industrial pollution, and even snow can accumulate on their surface. If not cleaned regularly, this grime can form a barrier between the sunlight and the photovoltaic cells, reducing energy production.

There are two primary methods to address this problem:

-

Manual Cleaning: Involves individuals physically washing the panels using brush, squeegees, water, and sometimes cleaning agents.

-

Automated Cleaning: Utilizes robotic systems or mechanized brush that clean panels on a scheduled basis, often without human intervention.

2. Effectiveness of Cleaning

Manual Cleaning

Manual cleaning can be highly effective when performed properly. Workers can spot-clean trouble areas, remove hardened grime, and adjust their techniques for different panel angles and installations.

Pros:

Cons:

Automated Cleaning Brush

Automated systems, especially robotic brush, offer consistent and efficient cleaning. These systems often require little or no water and can be programmed to clean during low-light hours to avoid thermal shock.

Pros:

-

Uniform and frequent cleaning.

-

Non-abrasive brush designed to minimize damage.

-

Ideal for large-scale solar farms.

-

Waterless options available (eco-friendly).

Cons:

3. Time and Labor Efficiency

Manual Cleaning

Manual cleaning is labor-intensive. Depending on the size of the installation, it may take hours or even days to clean all the panels. This approach also requires safety precautions, especially for rooftop systems.

Challenges:

Automated Cleaning

Automated brush, once installed, operate with minimal human input. Some systems can clean thousands of panels in a single day.

Advantages:

-

Quick and continuous operation.

-

Can be scheduled for off-peak hours.

-

Reduces labor costs and safety risks.

4. Cost Considerations

Initial Costs

-

Manual cleaning has low startup costs. Equipment is inexpensive, and workers can be hired as needed.

-

Automated systems involve high capital investment. A robotic cleaning system can cost thousands of dollars depending on the scale.

Long-Term Costs

-

Manual cleaning requires recurring labor expenses, insurance, and potential costs for damage or inefficiencies.

-

Automated systems require occasional maintenance but eliminate the need for ongoing labor.

Over a 5-10 year period, automated cleaning often becomes more economical for larger installations.

5. Water Usage and Environmental Impact

Manual Cleaning

Manual cleaning typically uses a significant amount of water, especially in dusty regions. This is a concern in areas with water scarcity.

Automated Systems

Many automated brush are designed to be waterless or use minimal water through misting. This makes them a sustainable choice, especially in arid climates.

6. Scalability

-

Manual cleaning is better suited for small-scale or irregular installations (e.g., complex rooftops).

-

Automated systems shine in large-scale deployments like utility-scale solar farms or ground-mounted installations.

For example, a solar farm with 10,000+ panels would require a team of workers for several days to clean manually, whereas automated systems can handle the same workload in a fraction of the time.

7. Maintenance and Reliability

Manual Cleaning

While basic, manual cleaning is vulnerable to human error and inconsistency. Additionally, frequent manual handling increases the risk of surface damage over time.

Automated Brush

Automated systems require periodic maintenance—like brush replacement or software updates—but they are generally built for durability. Many include sensors and remote monitoring to ensure optimal performance.

8. Safety Considerations

Manual cleaning poses safety risks such as falls, electric shock, and exposure to cleaning chemicals. Proper training and gear are essential.

Automated systems significantly reduce these risks by minimizing human involvement.

9. Case Studies and Real-World Applications

-

India: Many solar farms in Rajasthan and Gujarat have adopted robotic, waterless cleaning systems due to the dusty environment and water scarcity.

-

California: Utility companies are increasingly using semi-autonomous vehicles equipped with brush for large-scale solar farm maintenance.

-

Residential Users: In contrast, small rooftop systems are often still cleaned manually, sometimes even by the homeowners themselves.

10. Conclusion: Which Method is Better?

The best solar panel cleaning method depends on your specific needs:

|

Factor

|

Best Method

|

|

Small installations

|

Manual

|

|

Budget-conscious users

|

Manual (short-term)

|

|

Large-scale operations

|

Automated

|

|

Water scarcity regions

|

Automated (waterless)

|

|

Frequent cleaning needs

|

Automated

|

|

Precision spot-cleaning

|

Manual

|

Final Thought:

In the long run, automated cleaning systems offer a compelling value proposition for large installations due to their consistency, scalability, and lower operating costs. However, manual cleaning remains a viable and necessary solution for smaller, complex, or low-budget systems.

As solar technology advances, hybrid approaches combining both methods might become the norm—automated systems for regular maintenance, with periodic manual deep-cleaning for optimal performance.

FAQs

1. Can automated cleaning systems be used during rain?

Yes, many automated systems can be programmed to operate during rainy conditions, using rainwater to assist in loosening dirt for more effective cleaning.

2. Will automated brushes scratch or degrade solar panel surfaces over time?

Most automated brushes are made from soft, non-abrasive materials that are safe for solar panels. When used as intended, they should not cause surface damage.

3. Are there solar-powered automated cleaning systems?

Yes, some automated cleaning systems are solar-powered, making them energy-efficient and ideal for remote or off-grid installations.

4. How do manual and automated methods handle snow accumulation?

Manual cleaning is generally more effective for snow removal. Most automated systems are not built to handle heavy snow and may require additional tools or heated panels.

5. Can either method be used for vertical or wall-mounted solar panels?

Manual cleaning is typically better suited for vertical installations. Automated systems often struggle with steep or vertical surfaces due to gravity and mechanical limitations.