Contents:

Solid-state batteries represent a promising advancement in energy storage technology. Unlike traditional lithium-ion batteries that use liquid electrolytes to facilitate the flow of ions, solid-state batteries use a solid electrolyte. This key difference provides a range of benefits, including increased safety, longer lifespan, and higher energy density, which makes them particularly appealing for applications in electric vehicles (EVs) and portable electronics. Below, we’ll explore how solid-state batteries work, their advantages, challenges, and future potential.

How Solid-State Batteries Work

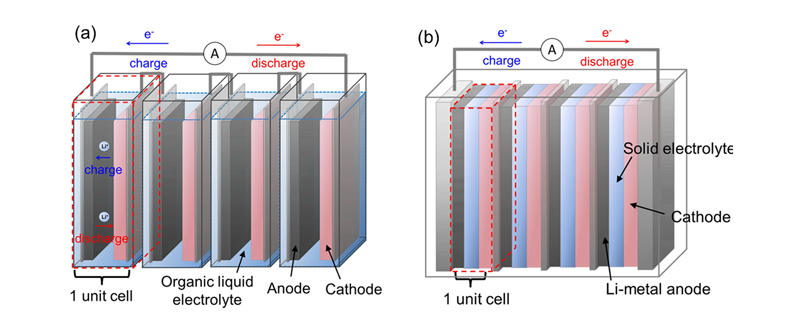

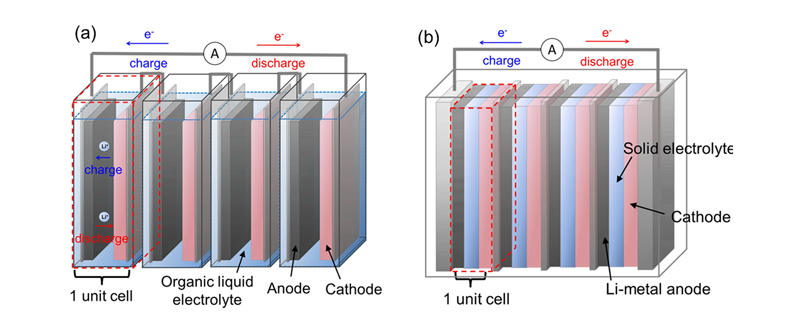

A typical battery operates by moving ions between a cathode and an anode. In conventional lithium-ion batteries, this transfer happens through a liquid electrolyte, which has some inherent risks and limitations. In contrast, solid-state batteries employ a solid electrolyte, often made from materials such as ceramics, glass, or polymers. This electrolyte not only enhances safety by reducing the risk of leaks and thermal runaway but also allows for a more compact and robust design.

Components of a Solid-State Battery

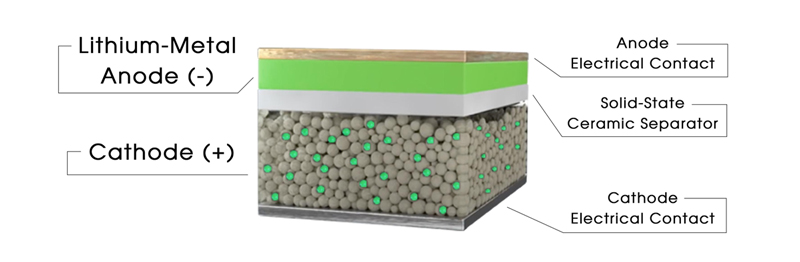

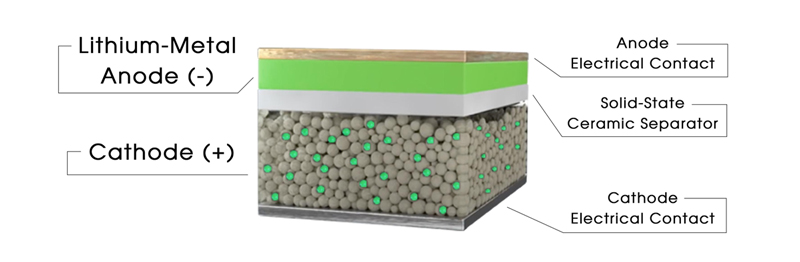

- Anode: The anode in solid-state batteries can be lithium metal or other solid materials. Lithium metal is preferred due to its high energy capacity, which increases the overall energy density of the battery.

-

Cathode: The cathode usually comprises lithium-containing compounds. Various compounds are being explored to optimize performance, stability, and cost.

-

Solid Electrolyte: Solid electrolytes may be composed of different materials, such as ceramic, polymer, or sulfide-based compounds. Each type has unique properties that impact the battery's performance and stability.

-

Current Collectors: These conductive layers facilitate the flow of electrons through the battery, ensuring efficient energy transfer.

How Energy is Stored and Released

When the battery charges, lithium ions move from the cathode through the solid electrolyte to the anode, where they are stored. During discharge, the ions reverse direction, moving from the anode to the cathode, thereby generating an electric current.

Advantages of Solid-State Batteries

| Feature |

Benefit |

| Increased Safety |

Solid-state batteries reduce fire risks by replacing flammable liquid electrolytes with non-flammable solid materials. |

| Higher Energy Density |

The use of lithium metal anodes allows solid-state batteries to achieve much higher energy densities, potentially doubling or tripling the range of EVs compared to conventional lithium-ion batteries. |

| Longer Lifespan |

The solid electrolyte reduces wear and tear, leading to longer cycle life and better performance over time. |

| Compact Design |

Solid electrolytes enable smaller, more energy-efficient designs, ideal for compact devices and EVs. |

| Temperature Stability |

Solid-state batteries perform well in a broader range of temperatures, reducing the need for complex cooling systems. |

Challenges in Developing Solid-State Batteries

While solid-state batteries offer numerous advantages, several technical challenges remain:

-

Manufacturing Complexity: Producing solid electrolytes and integrating them into batteries requires new manufacturing processes, which can be costly and complex.

-

Material Stability: Certain solid electrolytes, such as sulfides, can degrade over time or react with lithium, reducing battery life.

-

High Cost: The materials and technology involved in solid-state battery production are currently expensive, limiting their scalability for widespread commercial use.

-

Interface Issues: Ensuring a stable connection between the solid electrolyte and other components, such as the anode, is challenging. Poor interfacial contact can reduce performance and longevity.

Current Applications and Future Potential

Solid-state batteries are still largely in the development phase, with only a few prototypes available in the market. However, their potential is immense:

-

Electric Vehicles (EVs): The automotive industry is highly interested in solid-state batteries due to their high energy density and safety. Companies like Toyota, BMW, and QuantumScape are investing heavily in this technology.

-

Consumer Electronics: High-capacity, compact batteries could transform devices like smartphones and laptops, extending battery life and improving safety.

-

Renewable Energy Storage: Solid-state batteries could play a significant role in grid storage, balancing supply and demand for renewable energy sources.

Recent Innovations in Solid-State Battery Technology

As the demand for efficient and safe energy storage grows, researchers and companies worldwide are focusing on new materials and methods to improve solid-state battery technology. Key areas of innovation include:

-

New Electrolyte Materials: The development of stable, fast-conducting solid electrolytes is a critical factor for achieving commercial viability. Researchers are experimenting with ceramic, sulfide, and polymer electrolytes to optimize conductivity and thermal stability while minimizing manufacturing complexity.

-

Hybrid Solid-Liquid Batteries: Some manufacturers are exploring hybrid designs that use both solid and liquid electrolytes. This approach aims to leverage the best features of both, potentially reducing cost and improving performance while overcoming issues with interface stability.

-

3D Battery Architecture: Innovative 3D designs enhance surface area, enabling faster ion transport and higher energy densities without increasing the battery size. This design holds particular promise for compact applications, such as wearables and portable electronics, where space is at a premium.

-

High-Voltage Cathodes: New high-voltage cathode materials are being paired with solid electrolytes to improve energy density and stability. High-voltage materials allow for more energy storage in a smaller space, a critical factor for EVs and grid storage applications.

Key Players and Industry Developments

The global push for sustainable energy is driving significant investment in solid-state battery technology, with major companies and start-ups leading the charge:

-

Toyota: Toyota has announced plans to develop solid-state batteries for its electric vehicles, aiming to bring this technology to market by the late 2020s. The company’s research focuses on stability and cost-effectiveness, using sulfide-based electrolytes that enhance performance in a vehicle environment.

-

QuantumScape: This U.S.-based start-up, in partnership with Volkswagen, is working on a solid-state battery with an anode-free design, reducing material usage and boosting energy density. QuantumScape’s approach could make batteries both cheaper and more compact, a crucial advantage for EV manufacturers.

-

Solid Power: Supported by companies like Ford and BMW, Solid Power is developing all-solid-state batteries that use sulfide-based electrolytes, aiming to increase energy density while addressing interface stability issues.

-

Samsung SDI: Samsung has demonstrated prototype solid-state batteries for portable electronics and EVs. The company’s focus on energy density and miniaturization could redefine battery standards for consumer electronics.

Comparison with Conventional Lithium-Ion Batteries

While both solid-state and lithium-ion batteries are used to store energy, they differ significantly in performance, safety, and potential applications. Here’s a comparison of the two technologies:

|

Feature

|

Solid-State Battery

|

Lithium-Ion Battery

|

|

Energy Density

|

Higher, especially with lithium metal anodes, potentially increasing EV range by up to 50%

|

Moderate, constrained by liquid electrolyte properties

|

|

Safety

|

More stable, with lower risks of leaks and thermal runaway

|

Potentially flammable due to liquid electrolytes

|

|

Lifespan

|

Longer, with reduced wear and tear from solid electrolytes

|

Shorter, especially under high charge/discharge rates

|

|

Operating Temperature

|

Performs well in a wider range, reducing need for complex cooling

|

More limited, often requiring external temperature regulation

|

|

Manufacturing Cost

|

High, due to new materials and manufacturing processes

|

Currently lower, with mature production technology

|

|

Commercial Availability

|

In developmental stages with limited availability

|

Widely available and extensively used

|

Commercial Potential and Industry Impact of Solid-State Batteries

The potential of solid-state batteries extends well beyond electric vehicles and consumer electronics. Their unique benefits position them as key components in multiple industries, including renewable energy storage, aerospace, and medical devices.

-

Electric Vehicles (EVs): The automotive industry stands to gain significantly from solid-state battery technology. The increased energy density means EVs could achieve longer ranges with smaller, lighter batteries, addressing one of the most common barriers to EV adoption—range anxiety. Automakers are eager to harness these capabilities to offer vehicles with 400 to 600 miles of range on a single charge, making EVs more attractive to a broader market. Additionally, the enhanced safety profile of solid-state batteries offers an appealing selling point, as it could lead to reduced insurance costs and fewer safety recalls associated with battery-related incidents.

-

Consumer Electronics: In smartphones, laptops, and wearables, solid-state batteries could be transformative. The high energy density enables longer battery life without increasing device weight, making it easier for manufacturers to create ultra-thin devices with extensive battery longevity. Solid-state technology could also reduce the frequency of battery replacements, aligning with the growing consumer interest in sustainable, longer-lasting products. Moreover, solid-state batteries could support faster charging, allowing users to power up devices in minutes instead of hours.

-

Renewable Energy Storage: The renewable energy sector is increasingly focused on scalable energy storage solutions to address the intermittent nature of solar and wind power. Solid-state batteries could provide a more compact, long-lasting, and safer alternative for grid-scale storage, which is essential for balancing supply and demand in renewable energy systems. With their high-temperature stability, solid-state batteries are well-suited for regions where climate conditions might impact the efficiency of other battery types. These advantages could reduce the need for supplementary cooling systems, making them a cost-effective option for large-scale installations.

-

Medical Devices: The medical industry relies on portable, durable power sources for devices such as pacemakers, implantable defibrillators, and other life-supporting technology. Solid-state batteries’ stability, long life, and compact size make them ideal for such critical applications. With advancements in miniaturization, solid-state batteries could support the development of even smaller, more versatile devices, improving the quality of patient care and comfort.

-

Aerospace and Defense: Aerospace applications demand reliable, high-performance batteries that operate safely under extreme conditions. Solid-state batteries, with their superior energy density and stability, are well-suited for this purpose. They can handle harsh environments and maintain performance during rapid discharge cycles, critical for applications such as satellite power systems, unmanned aerial vehicles (UAVs), and spacecraft.

Environmental and Sustainability Considerations

With their longer lifespan, solid-state batteries align well with the movement toward sustainable energy solutions. Compared to traditional lithium-ion batteries, which degrade more rapidly and are often discarded after a few years, solid-state batteries have a greater potential to be reused or recycled, helping to reduce waste.

Reducing Resource Consumption

Solid-state batteries reduce the need for certain cooling systems and auxiliary materials required for safety in lithium-ion batteries, making them more resource-efficient. Since they can operate efficiently across a broader temperature range, they are less dependent on additional insulation, fire-proofing, and cooling equipment. This reduction not only lowers material requirements but also improves the battery's carbon footprint over its life cycle.

Recycling and Material Recovery

As solid-state battery technology matures, establishing robust recycling pathways will be essential. Conventional lithium-ion battery recycling methods may not be directly applicable due to the different materials used in solid-state batteries, particularly the solid electrolytes. To address this, researchers are investigating methods to safely extract and reuse the valuable components, such as lithium metal, used in solid-state batteries. This will ensure that these materials can be efficiently recycled back into the supply chain, contributing to a circular economy for battery materials.

Reduced Environmental Impact

The improved safety profile of solid-state batteries minimizes risks of thermal runaway and chemical leakage, which can lead to environmental contamination. Additionally, the extended lifecycle reduces the frequency of disposal, lessening the environmental burden associated with battery production and waste management.

Evolving Research and Development Landscape

As solid-state batteries inch closer to commercialization, ongoing research is tackling the remaining obstacles. New electrolyte materials and anode configurations are being tested to find the optimal balance of performance, cost, and longevity. Collaborative efforts among universities, research institutions, and companies are accelerating the discovery of solutions to these technical challenges, often involving novel approaches such as artificial intelligence (AI) and machine learning.

-

AI-Powered Material Discovery: Machine learning algorithms are being used to analyze vast datasets to predict the properties of new materials and identify the best candidates for solid electrolytes and other components. This approach reduces the time and cost associated with traditional trial-and-error experimentation, allowing researchers to focus on the most promising materials from the outset.

-

Additive Manufacturing and 3D Printing: Advanced manufacturing techniques, such as 3D printing, are being explored to create complex, layered designs for solid-state batteries. Additive manufacturing can enable precise control over material placement, resulting in batteries that are both compact and capable of achieving higher energy densities. This innovation holds potential for customizing batteries to fit specific shapes and power needs in small devices or aerospace applications.

-

Development of Interface Coatings: To improve the interface between the solid electrolyte and the lithium metal anode, researchers are developing thin, protective coatings. These coatings prevent unwanted reactions and degradation, effectively extending the battery’s cycle life and improving efficiency. This solution is especially beneficial for EV batteries, where longevity and performance are paramount.

-

Hybrid Solutions and Blended Electrolytes: Some researchers are exploring hybrid designs that combine liquid and solid electrolytes, or even multiple types of solid electrolytes. By blending materials, they aim to create batteries that retain the best qualities of each component while overcoming individual drawbacks. For example, combining ceramic and polymer electrolytes could result in a flexible yet durable battery suitable for a wide range of applications.

In conclusion, while solid-state battery technology still faces challenges related to cost, scalability, and interface stability, the progress in research and industry commitment signals a promising future. Through continued innovation, solid-state batteries have the potential to redefine standards across various sectors, ultimately shaping a safer, more efficient, and environmentally sustainable energy landscape.

FAQs