Contents:

Testing a lithium cell battery involves checking both its performance characteristics and its safety standards. Given the importance of lithium batteries in devices like smartphones, laptops, electric vehicles, and other electronics, understanding their status is crucial for optimal performance and safety. This guide provides a step-by-step approach to testing a lithium battery, covering the tools required, test procedures, and key metrics to assess.

1. Preparation and Safety Precautions

Lithium batteries store a considerable amount of energy in a small space, which, under certain conditions, can become volatile. Therefore, following safety guidelines is essential:

-

Wear protective gear: Safety glasses and gloves.

-

Ensure proper ventilation: Test in a well-ventilated area to prevent inhaling any fumes in case of a battery breach.

-

Avoid flammable materials nearby: Keep testing areas free from flammable materials.

-

Use protective equipment: Use a battery tester with a built-in fuse or safety circuit.

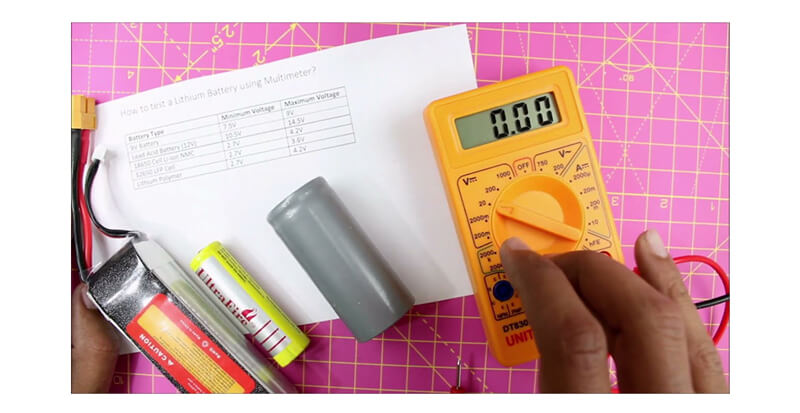

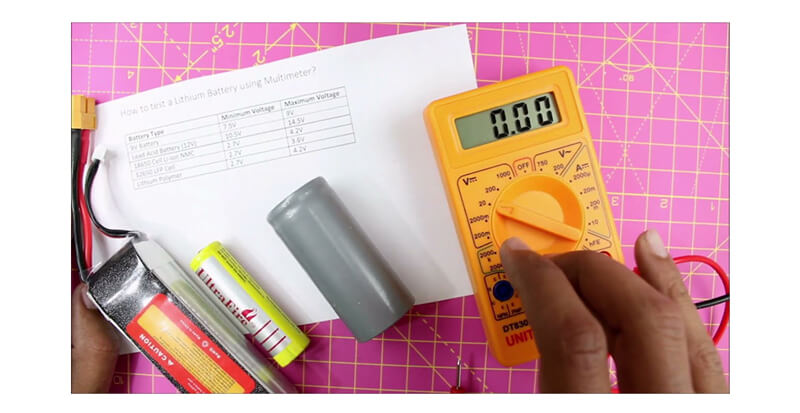

2. Tools for Testing Lithium Batteries

To ensure accurate results, use the right tools:

-

Multimeter: Measures voltage and resistance to check the battery's health.

-

Battery analyzer: Assesses capacity, internal resistance, and charging cycles.

-

Load tester: Helps evaluate the battery's performance under different loads.

-

Thermal camera or thermometer: Monitors temperature, which can indicate potential faults.

3. Basic Tests to Conduct on Lithium Batteries

Step 1: Visual Inspection

-

Look for any visible signs of damage, such as bulging, cracks, or leaks. Physical damage can impact the battery's safety and performance.

Step 2: Voltage Testing

-

Set the multimeter to measure DC voltage.

-

Connect the multimeter leads to the positive and negative terminals of the battery.

-

Record the voltage. For most lithium-ion cells, the fully charged voltage is around 4.2V, and a safe minimum is about 3.0V.

-

Voltage readings below 3.0V may indicate a dead or deeply discharged cell, which can lead to instability if recharged.

Step 3: Capacity Testing

-

A battery analyzer can provide a capacity test by discharging the battery completely and then measuring the amount of energy needed to recharge it to full capacity.

-

Compare the measured capacity to the manufacturer’s specified capacity. Decreased capacity over time is common but should not fall below 80% of the original capacity too quickly.

Step 4: Internal Resistance Testing

-

Higher internal resistance indicates degraded battery health.

-

Using the battery analyzer or a resistance meter, check the internal resistance in milliohms. For lithium-ion cells, values typically range between 50-100 milliohms for healthy batteries.

Step 5: Temperature Monitoring During Discharge

-

While discharging the battery, use a thermal camera or thermometer to monitor temperature changes.

-

Significant heating (above 45°C) during normal discharge could indicate issues such as internal short circuits or capacity deterioration.

Sample Data Table of Lithium Cell Battery Tests

The following table demonstrates how to organize test results for a lithium battery. Each parameter should be documented to assess battery performance over time.

|

Test Parameter

|

Measurement

|

Expected Range

|

Result

|

|

Voltage

|

4.1V

|

3.0V - 4.2V

|

Pass

|

|

Capacity

|

2800 mAh

|

Up to 3000 mAh

|

Pass

|

|

Internal Resistance

|

55 mΩ

|

50-100 mΩ

|

Pass

|

|

Temperature

|

35°C

|

Below 45°C

|

Pass

|

4. Interpreting the Results

The data collected from each of the tests helps determine whether the lithium battery is in good condition, needs maintenance, or requires replacement. If the voltage, capacity, and internal resistance are within acceptable ranges and the battery operates without excessive heating, it can be deemed safe and functional. However, if any metric falls outside the recommended range, the battery should be tested more frequently, monitored closely, or replaced if severely degraded.

5. Advanced Testing: Cycle Life Testing

For applications where batteries undergo extensive usage cycles, it’s advisable to conduct a cycle life test:

-

Cycle the battery between full charge and discharge: A battery cycle counter or analyzer will automate this process.

-

Evaluate degradation over time: Record capacity and internal resistance after a set number of cycles.

-

Predict longevity: Battery health typically deteriorates over hundreds or thousands of cycles, so predicting when capacity will fall below 80% is valuable for long-term planning.

6. Final Safety Check and Storage

Once all tests are complete, ensure that batteries intended for storage are at an optimal charge level (usually around 50%) to prolong their lifespan. Store lithium batteries in a cool, dry place to avoid self-discharge and degradation.

7. Performance Analysis Using Graphs

When testing lithium batteries, visual representations of data provide valuable insights into performance trends over time. A common approach is to plot test parameters such as capacity retention, internal resistance, and discharge temperature against the number of cycles. This graph enables you to observe the battery’s degradation and stability, helping with predictive maintenance and lifespan estimation.

This chart displays three metrics over multiple cycles:

-

Capacity Retention (%): Tracks how much of the original battery capacity is retained over each cycle.

-

Internal Resistance (mΩ): Shows how resistance increases over time, indicating gradual degradation.

-

Temperature (°C): Captures temperature rise during discharge, an important factor for identifying overheating risks.

8. Analyzing Key Trends

Using the chart above, we can identify several trends:

-

Capacity Decline: Lithium batteries naturally lose capacity as they cycle. Notably, if capacity retention falls below 80%, the battery is considered near the end of its effective life.

-

Increase in Internal Resistance: Over time, internal resistance increases as the cell ages, reducing its efficiency. This phenomenon may result in reduced output during peak loads and increased heat generation.

-

Temperature Changes: As cycles increase, the operating temperature of the battery under load may also rise. This trend often correlates with increased internal resistance and could signal the need for closer monitoring.

9. Battery Test Protocol Optimization

After analyzing test data, it may become apparent that adjusting the test protocol can improve the accuracy and relevance of the battery's assessment. For instance, increasing the frequency of cycle testing in batteries showing early signs of wear, or focusing on high-load tests to evaluate batteries used in power-demanding applications, can yield more actionable insights.

-

Enhanced Cycle Testing: Adding more cycle intervals, such as every 20 cycles instead of every 50, provides finer insights into early-stage degradation.

-

High-Load Testing: Testing batteries under peak load conditions provides a realistic picture of battery behavior under stress, as many batteries experience significant wear in these scenarios.

10. Practical Applications of Test Data

By performing and analyzing these tests, users can anticipate battery behavior in various real-world applications, such as consumer electronics, electric vehicles, or backup power systems. Test data informs when to replace batteries to prevent performance drops or failures in critical systems.

11. Long-Term Monitoring and Predictive Maintenance

Once a comprehensive testing protocol is established, integrating long-term monitoring can greatly benefit systems reliant on lithium batteries. Predictive maintenance based on test data helps preemptively identify when a battery is nearing its end of life, reducing unexpected downtimes and maintenance costs.

-

Data Logging: Regularly logging test data such as capacity, resistance, and temperature allows tracking over time. This historical data is crucial for identifying gradual declines that might not be evident in short-term testing.

-

Trend Analysis: Analyzing historical data helps establish performance benchmarks and predict when a battery may require replacement. If a battery's capacity decline or resistance increase accelerates, it may need replacement sooner than anticipated.

-

Machine Learning Models: For large-scale applications, machine learning models can be trained on historical battery data to predict failures. These models use past performance patterns to estimate remaining useful life, allowing for more accurate predictive maintenance.

12. Advanced Testing Techniques

In high-performance or critical applications, additional testing methods provide deeper insights into battery health.

-

Electrochemical Impedance Spectroscopy (EIS): This technique measures the impedance of a battery over a range of frequencies. EIS provides detailed insights into the internal chemical processes and degradation mechanisms.

-

Capacity Fade Analysis: Some testers employ capacity fade tests to measure how quickly a battery loses its ability to hold charge across multiple cycles. This is especially useful for applications where extended battery life is essential.

-

Thermal Runaway Testing: For applications with strict safety requirements, thermal runaway tests help determine a battery’s response to extreme heat and potential failure conditions. This test provides insights into a battery’s safe operating range, crucial for applications with high-temperature exposures.

13. Environmental Factors Affecting Battery Life

Environmental conditions such as temperature, humidity, and storage practices play a significant role in battery longevity.

-

Temperature Impact: Batteries stored at high temperatures or exposed to excessive heat during operation tend to age faster due to increased internal resistance and potential for thermal runaway.

-

Humidity and Moisture Exposure: Excessive moisture can lead to corrosion, especially on the battery terminals, which affects performance and safety.

-

Storage Voltage: Storing lithium batteries at around 50% charge rather than at full or depleted states helps slow down capacity fade during long-term storage.

14. Documenting Battery Test Results

For consistent monitoring and future reference, proper documentation of test results is essential. A well-maintained record system allows for easy comparison over time and aids in decision-making for maintenance and replacement.

-

Standardized Reporting Templates: Use templates to record each test’s date, conditions, and results. Standardization ensures consistency and aids in identifying outliers.

-

Digital Logs: Digital records provide easy access and analysis of historical data, allowing for trend analysis and efficient data management.

-

Visual Reporting Tools: Incorporate visual tools like charts and graphs to present data. Visual insights make it easier to understand trends and communicate findings to stakeholders.

FAQ: Lithium Battery Testing